Description

YEP Series High-Efficiency Three-Phase Asynchronous Motors The YEP series from Baolei Electric is a range of high-efficiency three-phase asynchronous motors developed on the basis of the YE general-purpose series. By optimizing the electromagnetic design, using low-loss silicon steel and improved cooling, YEP motors achieve higher efficiency, lower temperature rise, and reduced energy consumption under continuous operation.

Available in multiple frame sizes, power ratings, and pole configurations, YEP motors provide stable torque, low noise, and low vibration for modern industrial machinery. They are suitable for direct-on-line starting or inverter (VFD) control, making them an ideal choice for pumps, fans, compressors, blowers, gearboxes, convey, and other applications where energy saving and reliability are important.

YEP series motors adopt F-class insulation with temperature rise evaluated to class B, high-quality sealed bearings, and durable surface treatment for long service life in dusty or humid environments. Standard protection level up to IP54/IP55 and IC411 self-ventilated cooling ensure safe operation in a wide range of ambient conditions.

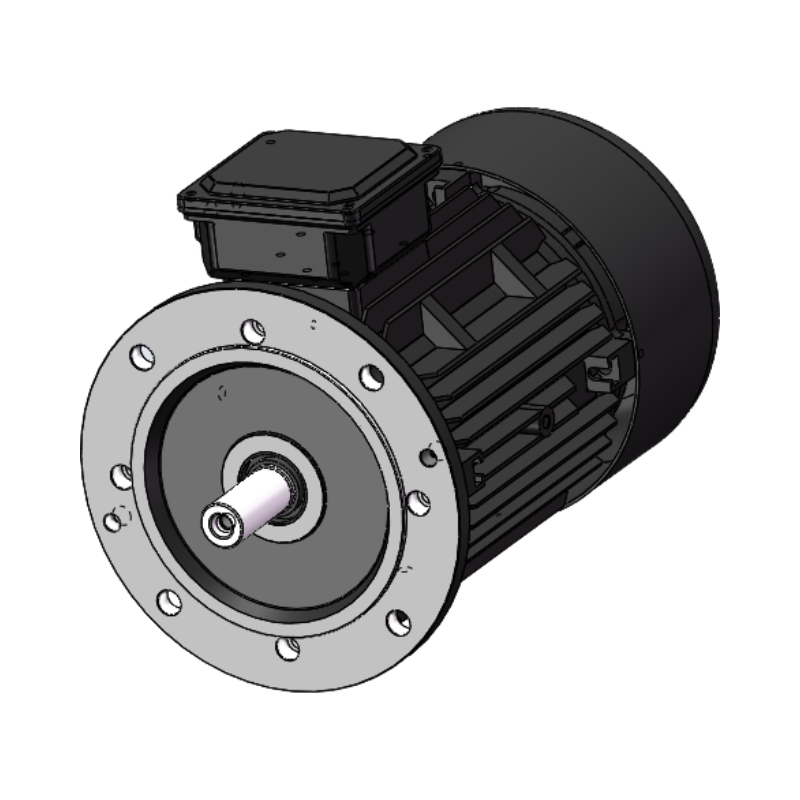

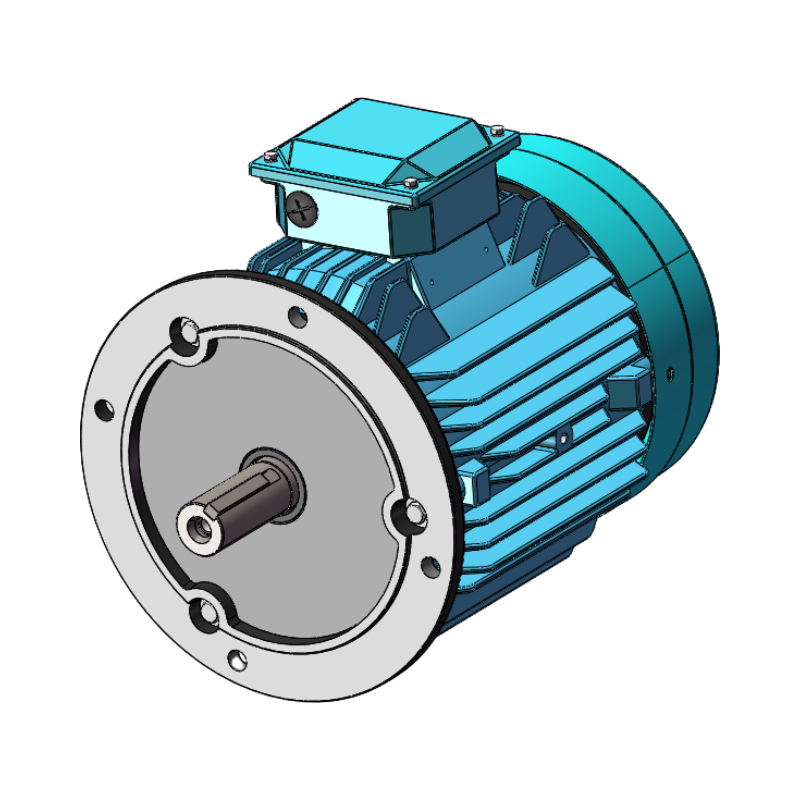

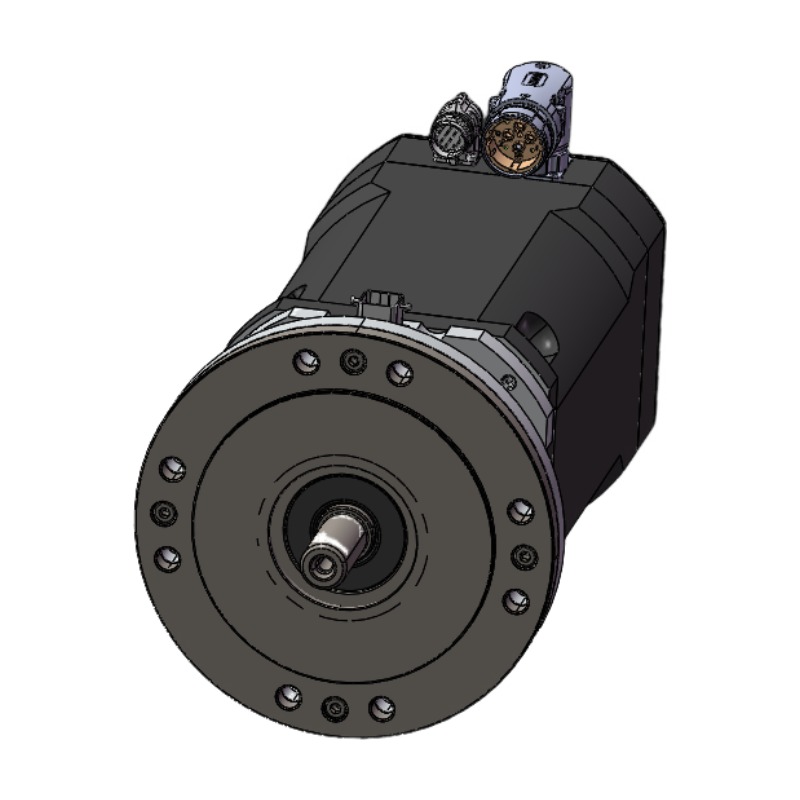

A variety of mounting arrangements (IMB3, IMB5, IMB35, etc.) and flexible terminal box positions make mechanical and electrical integration straightforward for OEMs and system builders. With high efficiency, consistent performance, and customization options for voltage, frequency, and mounting, the YEP series is a cost-effective high-efficiency upgrade over conventional three-phase asynchronous motors.

Technical Standards and Specifications:

| Item | Specification |

| Motor Type | General-purpose three-phase squirrel-cage asynchronous motor |

| Rated Voltage | Standard three-phase AC voltages such as 380 V / 400 V / 415 V (other voltages on request) |

| Rated Frequency | 50 Hz (60 Hz optional) |

| Power Supply | Three-phase mains supply or inverter (VFD) output |

| Power Range | Typical range from xx kW to xx kW (can be customized according to application) |

| Duty Rating | S1 continuous duty (other duty types available on request) |

| Number of Poles | 2, 4, 6 or 8 poles |

| Degree of Protection | Totally enclosed, IP54 (IP55 available on request) |

| Cooling Method | IC411 self-ventilated cooling with external fan |

| Mounting Arrangement | IMB3 (foot-mounted), IMB5 (flange-mounted), IMB35 (foot and flange) and other IEC mounting types |

| Insulation Class | Class F insulation, temperature rise evaluated to Class B |

| Vibration Grade | In accordance with IEC/ISO standards (e.g. IEC 60034 / ISO 2373 vibration limits) |

| Bearings | Double-sealed, low-noise deep-groove ball bearings |

| Terminal Box | Top or side mounted, rotatable in 90° steps (left/right entry optional) |

| Optional Accessories | Space heater, PTC thermistor, PT100 temperature sensor, thermal overload protector |

| Paint System | Standard industrial paint system; color and coating system can be customized |

| Supply Voltage Tolerance | Voltage variation ±10% |

| Installation Altitude | Up to 1,000–2,000 m above sea level (according to customer requirement) |

| Ambient Temperature | –15 °C to +40 °C (other ranges available by agreement) |

| Relative Humidity | Up to 95% (non-condensing) |

| Typical Applications | Pumps, fans, compressors, gearboxes, conveyors and other general industrial machinery |

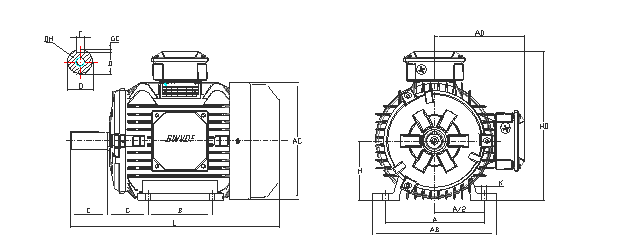

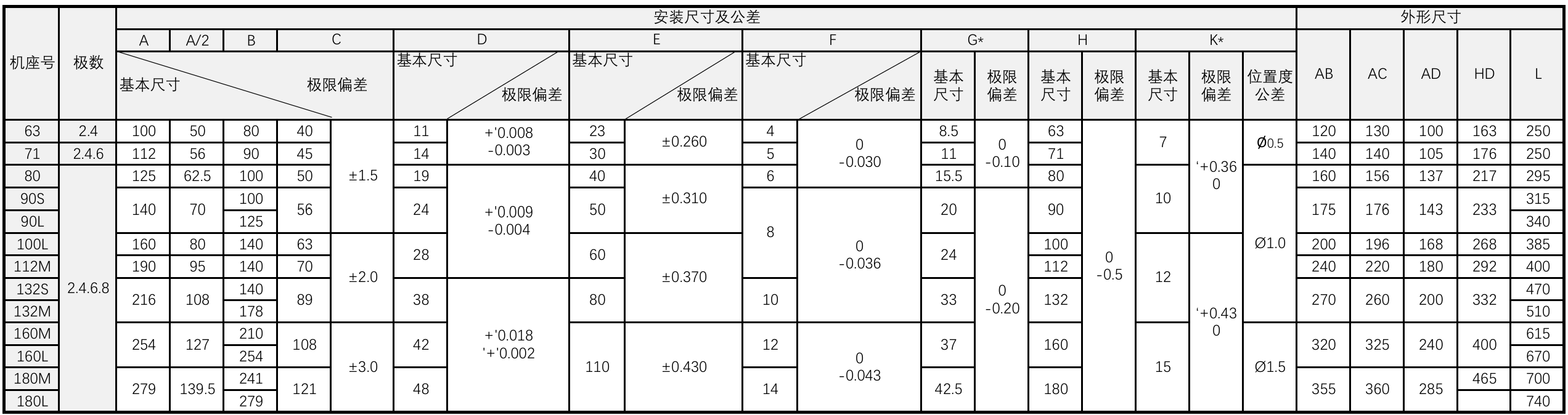

Installation Type and Dimensions:

The base does not include mounting feet; the end cover features a flange (with through holes).

YEP Technical Specifications:

| 1000 r/min 230/400V / 400/690V -S1-50Hz | |||||||||||

| TYPE | PN | IN | IN | nN | η | cosΦ | MN | MA/ | MK/ | IA/ | J |

| 230/400V | 400/690V | MN | MN | IN | (gm^2) | ||||||

| (kW) | (A) | (A) | (r/min) | (%) | (Nm) | ||||||

| YW 63S-6 | 0.09 | 0.85/0.49 | 850 | 39.6 | 0.67 | 1.01 | 2 | 2 | 1.8 | 0.28 | |

| YE 63L-6 | 0.12 | 1.13/0.65 | 865 | 42.8 | 0.62 | 1.32 | 2.1 | 2.2 | 1.9 | 0.35 | |

| YW 71L-4 | 0.37 | 1.89/1.09 | 1380 | 64.4 | 0.71 | 2.56 | 2 | 2.4 | 3.6 | 0.86 | |

| YW 80S-4 | 0.55 | 2.63/1.52 | 1375 | 71.5 | 0.73 | 3.82 | 1.9 | 2 | 3.3 | 1.09 | |

| YW 80L-4 | 0.75 | 3.64/2.10 | 1375 | 69.6 | 0.74 | 5.21 | 2 | 2.1 | 3.5 | 1.45 | |

| YW 90S-4 | 1.1 | 4.87/2.81 | 1395 | 76.2 | 0.74 | 7.53 | 2.3 | 2.6 | 4.4 | 2.35 | |

| YW 90L-4 | 1.5 | 6.15/3.55 | 1395 | 78.5 | 0.78 | 10.3 | 2.3 | 2.6 | 4.8 | 3.13 | |

| YW 100M-4 | 2.2 | 9.04/5.22 | 1440 | 81.1 | 0.74 | 14.6 | 2.3 | 3 | 5.1 | 4.5 | |

| YW100L-4 | 3 | 6.54/3.78 | 1415 | 82.6 | 0.8 | 20.2 | 2.5 | 2.9 | 5.4 | 6 | |

| YW 112M-4 | 4 | 8.30/4.79 | 1445 | 86 | 0.8 | 26.4 | 2.3 | 2.8 | 5.3 | 11 | |

| YW 132S-4 | 5.5 | 11.4/6.56 | 1445 | 85.8 | 0.81 | 36.5 | 2.1 | 2.7 | 5.5 | 24 | |

| YW 132M-4 | 7.5 | 14.8/8.55 | 1445 | 87 | 0.84 | 49.6 | 2.5 | 2.8 | 5.5 | 32 | |

| YW132L-4 | 9.2 | 18.8/10.9 | 1450 | 87.4 | 0.8 | 60.6 | 2.6 | 3.1 | 6 | 35 | |

| YW 160M-4 | 11 | 20.9/12.1 | 1455 | 88.4 | 0.85 | 72.2 | 2.4 | 2.9 | 6.5 | 50 | |

| YW 160L-4 | 15 | 28.2/16.3 | 1460 | 90 | 0.85 | 98.1 | 2.9 | 3.5 | 7.5 | 67 | |

| YW 180M-4 | 18.5 | 36.4/21 | 1460 | 90 | 0.83 | 121.7 | 3.2 | 3.8 | 7.5 | 80 | |

| YW 180L-4 | 22 | 43/25.8 | 1455 | 90.5 | 0.83 | 145.1 | 3.3 | 3.8 | 7.5 | 92 | |

| 1500/3000 r/min 400V △/YY -S1-50Hz | ||||||||||

| TYPE | PN

(kW) |

IN

400V (A) |

nN

(r/min) |

η

(%) |

cosΦ | MN

(Nm) |

MA/

MN |

MK/

MN |

IA/

IN |

J

(gm^2) |

| YW 63S-4/2 | 0.10

0.15 |

0.64

0.73 |

1415

2840 |

38.7

43.6 |

0.58

0.68 |

0.67

0.50 |

3.3

3.1 |

3.6

3.8 |

2.5

2.9 |

0.21 |

| YW 63L-4/2 | 0.15

0.19 |

0.95

0.95 |

1400

2850 |

40.0

43.7 |

0.57

0.66 |

1.02

0.64 |

2.9

3.3 |

3.1

4.0 |

2.2

2.9 |

0.28 |

| YW 71S-4/2 | 0.21

0.28 |

0.66

0.80 |

1410

2780 |

63.2

58.6 |

0.73

0.86 |

1.42

0.96 |

2.1

2.5 |

2.3

2.7 |

3.6

3.9 |

0.72 |

| YW 71L-4/2 | 0.30

0.45 |

0.98

1.30 |

1385

2715 |

59.2

56.7 |

0.75

0.88 |

2.07

1.58 |

2.1

1.6 |

2.1

1.9 |

3.3

3.4 |

0.86 |

| YW 80S-4/2 | 0.48

0.60 |

1.30

1.66 |

1390

2785 |

68.9

63.9 |

0.77

0.82 |

3.30

2.06 |

1.7

1.8 |

1.8

2.0 |

3.3

3.6 |

1.09 |

| YW 80L-4/2 | 0.70

0.85 |

1.84

2.34 |

1355

2770 |

69.9

65.5 |

0.79

0.80 |

4.93

2.93 |

1.6

2.0 |

1.7

2.0 |

3.3

3.6 |

1.45 |

| 750/1500 r/min 400V △/YY -S1 | ||||||||||

| 50Hz | ||||||||||

| TYPE | PN | IN | nN | η | cosΦ | MN | MA/ | MK/ | IA/ | J |

| 400V | MN | MN | IN | (gm^2) | ||||||

| (kW) | (A) | (r/min) | (%) | (Nm) | ||||||

| YW 71S-8/4 | 0.12 | 0.76 | 670 | 32.6 | 0.7 | 1.42 | 1.4 | 1.5 | 1.9 | 0.91 |

| 0.18 | 0.57 | 1350 | 55.7 | 0.82 | 0.96 | 1.4 | 1.5 | 3.2 | ||

| YW 71L-8/4 | 0.18 | 0.92 | 620 | 36.9 | 0.78 | 2.07 | 1.6 | 1.7 | 2 | 1.2 |

| 0.25 | 0.64 | 1410 | 68.5 | 0.82 | 1.58 | 1.8 | 2 | 3.9 | ||

| YW 80S-8/4 | 0.25 | 1.2 | 690 | 38.8 | 0.6 | 3.3 | 1.5 | 1.7 | 2.6 | 2.2 |

| 0.37 | 1.2 | 1400 | 62.8 | 0.71 | 2.06 | 1.5 | 1.6 | 3.8 | ||

| YW 80L-8/4 | 0.37 | 1.71 | 680 | 41.1 | 0.76 | 4.93 | 1.7 | 1.9 | 2.3 | 2.8 |

| 0.55 | 1.43 | 1380 | 73.1 | 0.76 | 2.93 | 1.8 | 2 | 3.8 | ||

| YW 90S-8/4 | 0.4 | 1.81 | 700 | 39.9 | 0.8 | 7.5 | 1.6 | 1.7 | 2.7 | 3.7 |

| 0.75 | 2 | 1380 | 66 | 0.82 | 4.81 | 1.5 | 1.9 | 3.6 | ||

| YW 132M-4/2 | 6.5 | 13 | 1455 | 87 | 0.83 | 42.81 | 2.2 | 2.6 | 5.4 | 31.7 |

| 8 | 18 | 2930 | 81.2 | 0.79 | 26.21 | 2.6 | 2.9 | 6.2 | ||

| YW 160M-4/2 | 9.3 | 18.3 | 1455 | 87 | 0.87 | 61.04 | 2 | 2.6 | 6.7 | 43 |

| 11.5 | 23.4 | 2930 | 80 | 0.89 | 37.48 | 1.8 | 2.4 | 7.4 | ||

| YW 160L-4/2 | 13 | 25.6 | 1455 | 88 | 0.84 | 85.33 | 2.5 | 3 | 7.6 | 60 |

| 17 | 32 | 2930 | 87 | 0.88 | 55.41 | 2.8 | 3 | 8.5 | ||

| 3600 r/min 460V -S1

60Hz |

||||||||||

| TYPE | PN

(kW) |

IN

460V (A) |

nN

(r/min) |

η

(%) |

cosΦ | MN

(Nm) |

MA/

MN |

MK/

MN |

IA/

IN |

J

(gm^2) |

| YW 63S-2 | 0.21 | 0.52 | 3315 | 60.4 | 0.84 | 0.60 | 2.4 | 2.4 | 3.3 | 0.21 |

| YW 63L-2 | 0.29 | 0.70 | 3320 | 59.8 | 0.87 | 0.83 | 2.3 | 2.5 | 3.4 | 0.28 |

| YW 71S-2 | 0.37 | 0.94 | 3460 | 65.9 | 0.75 | 1.02 | 1.8 | 2.4 | 3.8 | 0.35 |

| YW 71L-2 | 0.63 | 1.21 | 3440 | 78.8 | 0.83 | 1.75 | 2.6 | 2.6 | 5.0 | 0.45 |

| YW 80S-2 | 0.86 | 1.73 | 3380 | 71.8 | 0.87 | 2.43 | 2.2 | 2.2 | 4.6 | 0.67 |

| YW 80L-2 | 1.27 | 2.48 | 3390 | 76.6 | 0.84 | 3.58 | 3.3 | 3.3 | 5.4 | 0.90 |

| YW 90S-2 | 1.75 | 3.20 | 3385 | 78.1 | 0.88 | 4.94 | 2.5 | 2.5 | 5.0 | 1.40 |

| YW 90L-2 | 2.53 | 4.30 | 3380 | 82.1 | 0.90 | 7.10 | 1.9 | 2.5 | 5.7 | 1.80 |

| YW 100L-2 | 3.45 | 6.84 | 3360 | 81.3 | 0.78 | 9.80 | 2.2 | 2.5 | 4.6 | 2.80 |

| YW 112M-2 | 4.6 | 7.50 | 3480 | 88.6 | 0.87 | 12.6 | 2.4 | 2.4 | 4.8 | 5.50 |

| YW 132S-2 | 6.3 | 12.0 | 3445 | 80.5 | 0.82 | 17.5 | 2.2 | 2.2 | 4.6 | 10.0 |

| YW 132M-2 | 12.6 | 20.7 | 3460 | 83.1 | 0.92 | 34.8 | 1.9 | 2.1 | 5.1 | 18.9 |