Description

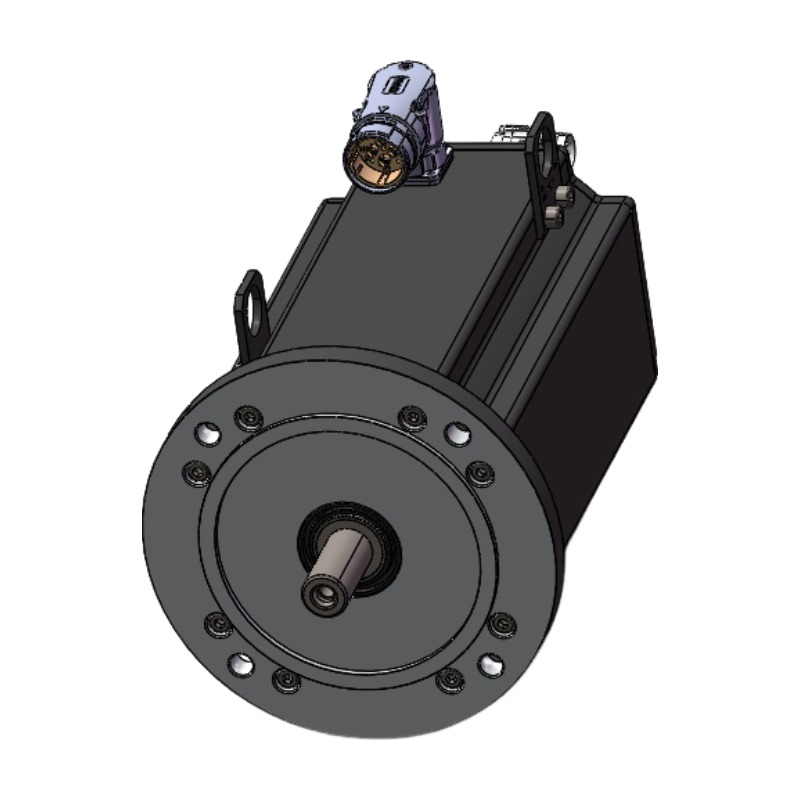

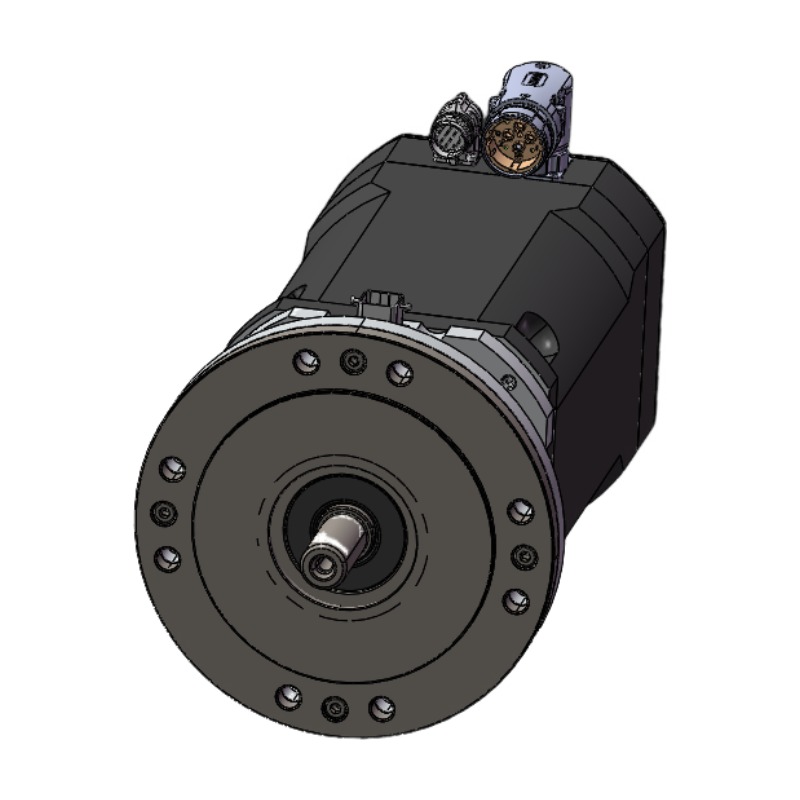

BFLP series wind turbine pitch motors are permanent magnet synchronous servo motors specially developed for blade pitch systems. With a simple and robust construction, these motors offer high operational reliability, long service life, and largely maintenance-free operation, making them an excellent choice for modern onshore and offshore wind turbines.

Thanks to permanent magnet synchronous servo technology, BFLP motors provide high starting torque, strong overload capability, and very fast dynamic response. This allows precise and smooth blade pitch adjustment under rapidly changing wind conditions, improving turbine efficiency and reducing mechanical stress on the pitch gearbox and hub. The motors run with low vibration and low noise, contributing to stable and accurate pitch control during normal operation and emergency events.

High efficiency and energy-saving performance are key advantages of the BFLP series. The motors are designed to reduce power losses in the pitch system, helping OEMs and wind farm owners increase overall turbine output and lower lifecycle energy consumption. Standard designs adopt B5 flange mounting and IC01 self-ventilated cooling, with protection class IP65 and F-class insulation for reliable operation in dusty, humid, and coastal environments.

BFLP pitch motors are suitable for ambient conditions of altitude 0–2000 m, operating temperature from −35°C to +5.5 °C, and relative humidity from 5% to 95%, making them ideal for cold-climate and harsh wind farm locations. Various brake options can be supplied according to customer requirements, and rotary resolvers are available for high-accuracy feedback to the pitch control system. Each motor is manufactured under strict quality control and tested for electrical performance, insulation strength, and mechanical reliability. With high efficiency, excellent low-temperature capabilities, and flexible configuration options, the BFLP series provides a premium pitch motor solution for wind turbine OEMs and service companies seeking advanced servo technology.

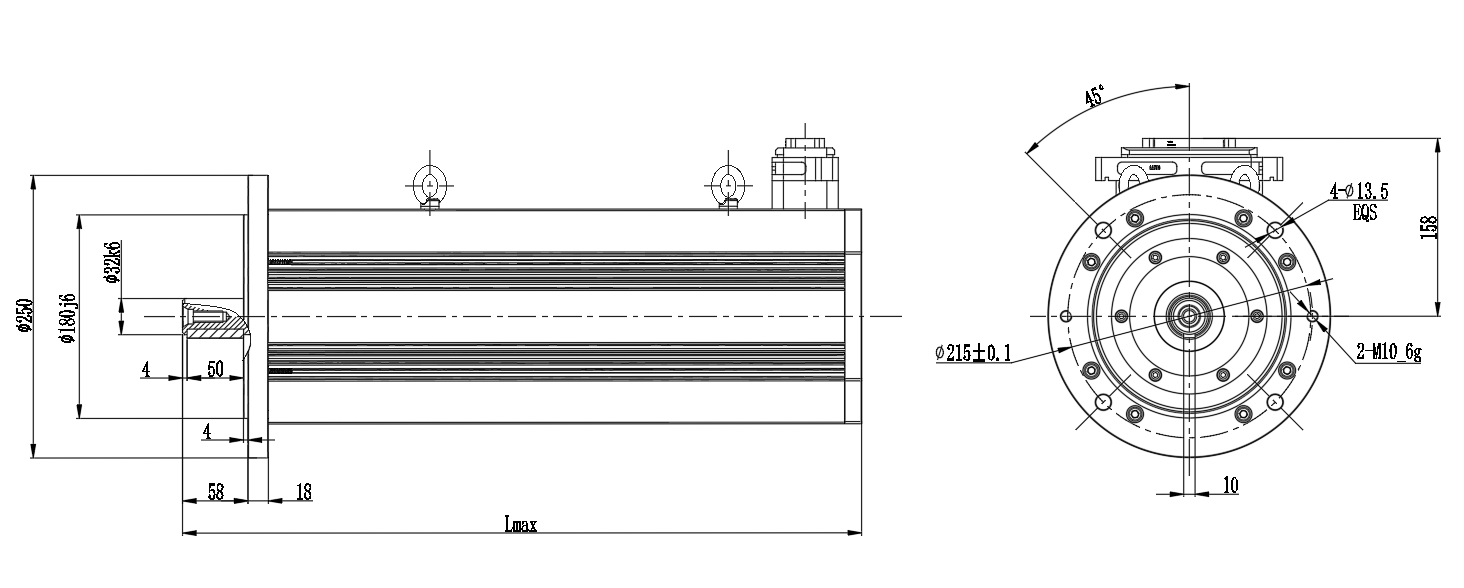

| Model | VDC | A | kW | Nm | r/min | brake | Work schedule | L1max mm |

| BFLP130A8-150S-SM | 380 | 11.1 | 5.8 | 28 | 2000 (133.3Hz) | 220V 1000min-1 | 205VDC 100 Nm | 490 |

| BFLP180A10-100S-SM | 380 | 21.8 | 4.5 | 28.7 | 1500 (125Hz) | 138V 1000min-1 | 24VDC 100 Nm | 450 |

| BFLP190A8-100S-SM | 380 | 21.8 | 4.4 | 28 | 1500 (100Hz) | 78.2V 1000min-1 | 24VDC 100 Nm | 450 |

| BFLP190A8-120S-SM | 380 | 31 | 6.1 | 39 | 1500 (100Hz) | 77.5V 1000min-1 | 24VDC 100 Nm | 480 |

| BFLP190A6-260S-SM | 155 | 45 | 8.2 | 52 | 1500 (75Hz) | 96.4V 1000min-1 | 24VDC 100 Nm | 670 |

| BFLP190D8-130S-SM | 380 | 22 | 6.9 | 33 | 2000 (133.3Hz) | 124V 1000min-1 | 24VDC 110 Nm | 460 |

| BFLP190F8-180S-SM | 380 | 21 | 9.4 | 45 | 2000 (133.3Hz) | 130.8V 1000min-1 | 24VDC 110 Nm | 505 |

| BFLP190M6-270S-SM | 400 | 29 | 12.4 | 59.4 | 2000 (100Hz) | 73.4V 1000min-1 | 150VDC 160 Nm | 610 |

| BFLP290N8-220S-SM | 275 | 52 | 20.4 | 130 | 1500 (100Hz) | 171V 1000min-1 | 24VDC 110 Nm | 650 |