Description

BPSM Three-Phase Permanent Magnet Synchronous Servo Motors

1.1 Features of BPSM Servo Motors

BPSM series AC permanent magnet synchronous servo motors from Baolei Electric are developed with independent intellectual property rights. They adopt high-performance rare-earth permanent magnet rotors and offer the following key features:

-

Low inertia & high power density – compact size with high torque output and excellent acceleration and deceleration capability.

-

Strong overload capability – suitable for applications with frequent start/stop and high peak torque demands.

-

Extremely low torque ripple & low noise – three-phase sinusoidal design provides smooth operation and quiet running.

-

Attractive appearance & robust design – suitable for harsh industrial environments with a high cost-performance ratio.

-

High-performance rare-earth magnet rotor – high torque, low inertia, and fast dynamic response.

-

Three-phase sinusoidal excitation – excellent low-speed smoothness and precise speed control.

-

F-class insulation with built-in thermal protector – enhances reliability and protects the motor from overheating.

-

Flexible feedback options – incremental or absolute optical encoders and resolvers are available.

-

High protection level – IP65 enclosure with convenient, quick-connect cable interfaces.

-

Flexible mounting – free and easy vertical mounting options for various machine layouts.

2. Handling, Storage, and Transportation of BPSM Servo Motors

2.1 Safety Instructions

When operating or installing BPSM servo motors, the following precautions must be observed:

-

Mechanical installation must be carried out by personnel with professional mechanical installation knowledge.

-

Electrical installation must be carried out by personnel with professional electrical knowledge.

-

Before unpacking or installing the servo motor, operators must thoroughly read and understand the motor documentation and be fully aware of the relevant safety precautions.

-

Incorrect mechanical or electrical handling may result in personal injury or damage to the equipment.

2.2 Storage and Transportation

-

Storage temperature: –25 °C to +55 °C, no icing.

-

Relative humidity: 5 % – 90 %, non-condensing.

-

Packaging must not be subjected to heavy loads or stacking pressure.

-

Keep away from corrosive and flammable gases, oil mist, and excessive dust.

-

Storage time: no special limitation under proper conditions.

-

During transportation, avoid impact and heavy pressure, and handle the motor with care.

3. Technical Characteristics of BPSM Servo Motors

3.1 General Technical Characteristics

-

Environmental conditions:

-

Ambient temperature: 5 °C to +40 °C.

-

Altitude: ≤ 1000 m above sea level.

Under these conditions, the motor can deliver its rated output.

-

-

Humidity: Relative humidity < RH 90 %, non-condensing.

-

Power derating: When ambient temperature is 40 °C–50 °C and the installation altitude exceeds 1000 m,

The output power should be reduced by 1.5 % for every additional 100 m. -

Fail-safe brake (optional):

-

When the motor is not energized or in the event of a sudden power failure, the brake engages to prevent shaft rotation, avoiding equipment damage or personal injury.

-

During normal operation, the brake is energized and released, allowing free shaft rotation.

-

-

Bearings:

-

All BPSM servo motors use imported, single-row, double-sealed deep-groove ball bearings with high/low temperature grease.

-

Bearing service life is not less than 20,000 hours under normal load conditions.

-

3.2 Electrical Characteristics

-

The servo drive system must be designed to minimize electromagnetic interference from surrounding equipment and to reduce interference to other devices.

-

The motor protective earth (PE) must be short, thick, and reliably connected to the protective earth (standard ground).

-

Shielded cables must be connected to a large metal reference plane to suppress high-frequency interference.

-

The connection of protective earth and shielding must be clearly distinguished and must not be mixed.

-

Cables between the motor and servo drive must be shielded:

-

Power cable capacitance: not less than 150 pF/m.

-

Position feedback cable capacitance: not less than 120 pF/m.

-

3.3 Mechanical Characteristics

-

Fastening screws must be regularly inspected to prevent loosening or falling off.

-

The motor housing must not be subjected to heavy impact or external force to avoid damage.

-

During normal operation of the mechanism, cleaning the external surface while running is strictly prohibited to avoid injury.

-

During installation, the load shaft must be precisely aligned and concentric with the shaft; otherwise, shaft breakage or damage to the driven mechanism may occur.

-

When mounting pulleys, gears, helical gears, or planetary gearboxes on the motor shaft, the axial (Fa) and radial (Fr) loads must be checked against the motor’s allowable load values.

-

The design must satisfy the following checks:

dmin≥2×Tm/Frd_{min} ge 2 times T_m / F_r

where dₘᵢₙ is the minimum diameter of the pulley/gear, and Tₘ is the motor peak torque.

Ensuring this relationship helps prevent damage to the motor shaft and bearings.

Technical Specifications for the BPSM Series:

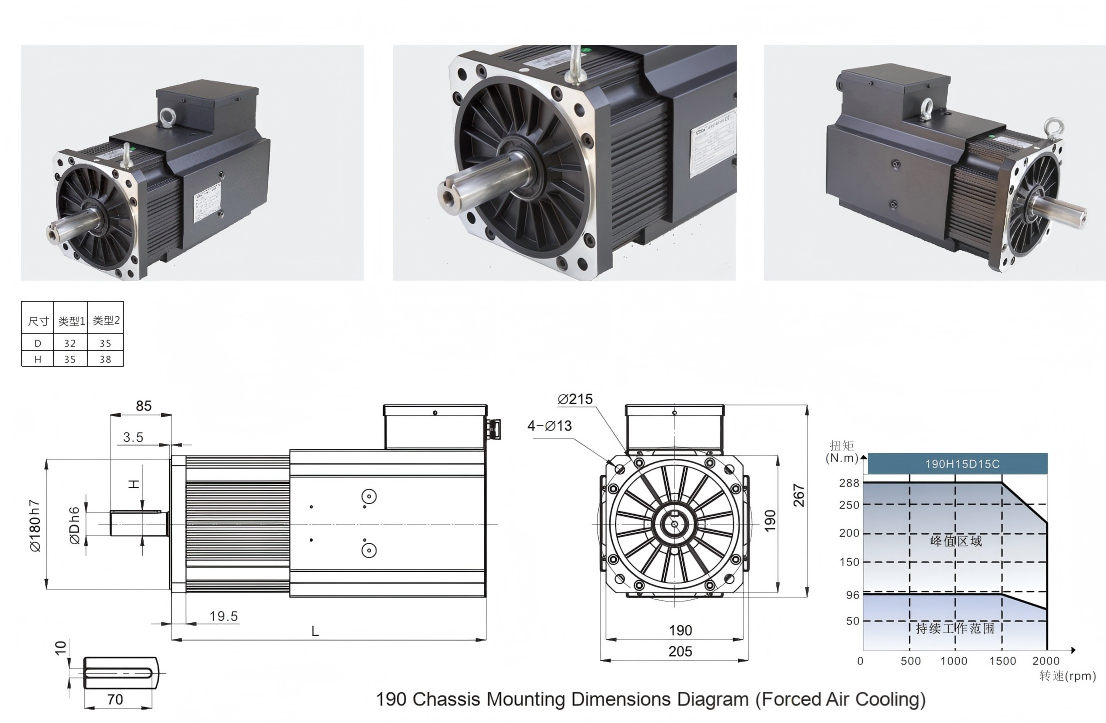

| Frame number Forced air cooling 190 | ||||||||||||||

| Model | N.m | Vac | rpm | kW | A | Kt N.m/A |

V/krpm | rpm | N.m | Kg.cm² | Poles | Kg | mm | mm |

| 190H11D30C | 35 | 380 | 3000 | 11.0 | 25.4 | 1.6 | 95 | 3600 | 105 | 68 | 10 | 30 | 341 | 441 |

| 190H11D20C | 53 | 380 | 2000 | 11.0 | 30.7 | 2.4 | 144 | 2500 | 158 | 89 | 10 | 33 | 381 | 441 |

| 190H11D15C | 70 | 380 | 1500 | 11.0 | 26.8 | 2.9 | 176 | 2000 | 210 | 95 | 10 | 34 | 381 | 441 |

| 190H13D17C | 70 | 380 | 1700 | 12.5 | 27.0 | 2.9 | 174 | 2210 | 210 | 95 | 10 | 34 | 381 | 441 |

| 190H15D20C | 72 | 380 | 2000 | 15.0 | 41.8 | 2.4 | 144 | 2500 | 210 | 130 | 10 | 37 | 441 | 496 |

| 190H22D30C | 70 | 380 | 3000 | 20.0 | 48.4 | 1.6 | 99 | 3600 | 210 | 130 | 10 | 37 | 441 | 496 |

| 190H15D15C | 96 | 380 | 1500 | 15.0 | 32.0 | 2.8 | 171 | 2000 | 288 | 130 | 10 | 39 | 441 | 496 |

| 190H17D17C | 96 | 380 | 1700 | 17.0 | 37.5 | 2.8 | 172 | 2210 | 288 | 130 | 10 | 39 | 441 | 496 |

| 190H20D20C | 96 | 380 | 2000 | 20.0 | 43.0 | 2.4 | 147 | 2500 | 288 | 130 | 10 | 39 | 441 | 496 |

| 190H19D15C | 118 | 380 | 1500 | 18.5 | 40.0 | 3.2 | 195 | 2000 | 354 | 145 | 10 | 41 | 456 | 516 |

| 190H21D17C | 118 | 380 | 1700 | 21.0 | 45.0 | 2.9 | 173 | 2210 | 354 | 145 | 10 | 41 | 456 | 516 |

| 190H25D20C | 118 | 380 | 2000 | 25.0 | 56.0 | 2.3 | 141 | 2500 | 354 | 145 | 10 | 41 | 456 | 516 |

| 190H22D15C | 140 | 380 | 1500 | 22.0 | 48.0 | 3.2 | 195 | 2000 | 420 | 172 | 10 | 45 | 496 | 556 |

| 190H25D17C | 140 | 380 | 1700 | 25.0 | 55.0 | 2.8 | 169 | 2210 | 420 | 172 | 10 | 45 | 496 | 556 |

| 190H29D20C | 140 | 380 | 2000 | 29.0 | 65.0 | 2.4 | 143 | 2500 | 420 | 172 | 10 | 45 | 496 | 556 |

| Motor Insulation Class: H; Thermal Protection: Pt100, KTY Optional: Protection Rating: IP65 (excluding fan guard); Wiring Method: Aviation Connector or Junction Box; Fan Voltage: 220V; Duty Cycle: 51 | ||||||||||||||

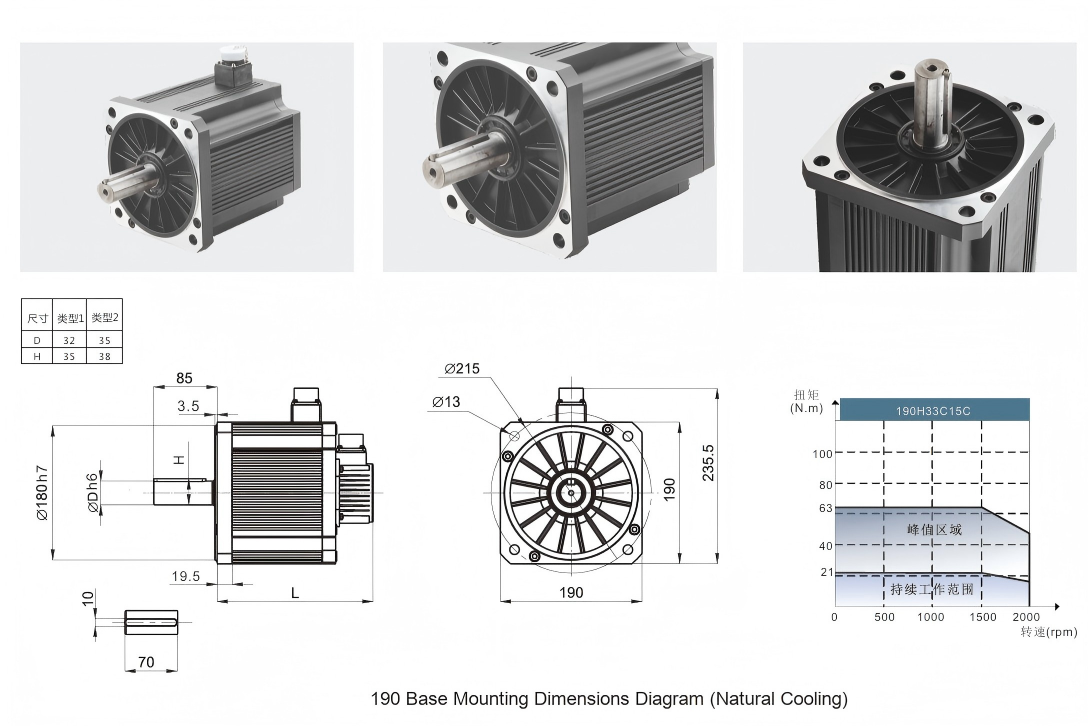

| Frame number Natural cooling 190 | ||||||||||||||

| Model | N.m | Vac | rpm | kW | A | Kt N.m/A |

V/krpm | rpm | N.m | Kg.cm² | Poles | Kg | mm | mm |

| 190H33C15C | 21 | 380 | 1500 | 3.3 | 8.2 | 2.9 | 175 | 2000 | 63 | 40 | 10 | 16 | 208 | 268 |

| 190H44C20C | 21 | 380 | 2000 | 4.4 | 10.2 | 2.3 | 140 | 2500 | 63 | 40 | 10 | 16 | 208 | 268 |

| 190H55C25C | 21 | 380 | 2500 | 5.5 | 13.0 | 1.8 | 110 | 3000 | 63 | 40 | 10 | 16 | 208 | 268 |

| 190H65C30C | 21 | 380 | 3000 | 6.5 | 15.3 | 1.5 | 93 | 3600 | 63 | 40 | 10 | 16 | 208 | 268 |

| 190H40C15C | 26 | 380 | 1500 | 4.0 | 9.4 | 3.0 | 183 | 2000 | 78 | 47 | 10 | 18 | 208 | 268 |

| 190H55C20C | 26 | 380 | 2000 | 5.5 | 13.2 | 2.2 | 135 | 2500 | 78 | 47 | 10 | 18 | 208 | 268 |

| 190H70C25C | 26 | 380 | 2500 | 7.0 | 16.8 | 1.8 | 108 | 3000 | 78 | 47 | 10 | 18 | 208 | 268 |

| 190H80C30C | 26 | 380 | 3000 | 8.0 | 19.3 | 1.5 | 90 | 3600 | 78 | 47 | 10 | 18 | 208 | 268 |

| 190H55C15C | 35 | 380 | 1500 | 5.5 | 12.6 | 3.1 | 189 | 2000 | 105 | 68 | 10 | 23 | 238 | 338 |

| 190H75C20C | 35 | 380 | 2000 | 7.5 | 17.0 | 2.4 | 144 | 2500 | 105 | 68 | 10 | 23 | 238 | 338 |

| 190H90C25C | 35 | 380 | 2500 | 9.0 | 20.9 | 1.9 | 113 | 3000 | 105 | 68 | 10 | 23 | 238 | 338 |

| 190H11D30C | 35 | 380 | 3000 | 11.0 | 22.5 | 1.8 | 108 | 3600 | 105 | 95 | 10 | 30 | 278 | 338 |

| 190H75C15C | 48 | 380 | 1500 | 7.5 | 16.7 | 3.2 | 195 | 2000 | 144 | 95 | 10 | 30 | 278 | 338 |

| Motor insulation class: H; Thermal protection: PT100, KTY optional; Protection rating: IP65; Wiring method: Aviation connector; Brake: Optional Duty cycle: 51; Voltage rating: 380V (optional) | ||||||||||||||