Wind turbine technology is at the forefront of converting wind energy into clean, renewable electricity. By converting the wind’s kinetic energy into electrical energy, wind turbines provide a sustainable power source that helps reduce greenhouse gases and reliance on fossil fuels. However, wind energy is an intermittent renewable energy source, meaning its availability depends on wind conditions. The initial capital investment for wind turbines can be substantial, although costs are decreasing with technological advancements. This article explores how wind turbines work, the different types available, and their role in wind power plants and wind farms, highlighting innovations from industry leaders like Retek Industrial.

How Wind Turbines Work

Wind turbines operate by capturing the kinetic energy from the wind and converting it into mechanical energy, which is then transformed into electric power through an electrical generator. As wind flows over the rotor blades, it creates lift and drag forces that cause the blades to rotate. Differences in air pressure across the surfaces of the blades generate lift, contributing to their rotation. This rotation spins the main rotor shaft connected to the electric generator—also known as a wind generator—producing electricity that can be fed into the power grid.

The rotor provides low-speed incoming rotation, which is increased by the gearbox to enable effective electricity generation. The maximum theoretical power output of a wind turbine is determined by Betz’s law, which states that no turbine can capture more than 59.3% of the kinetic energy in wind.

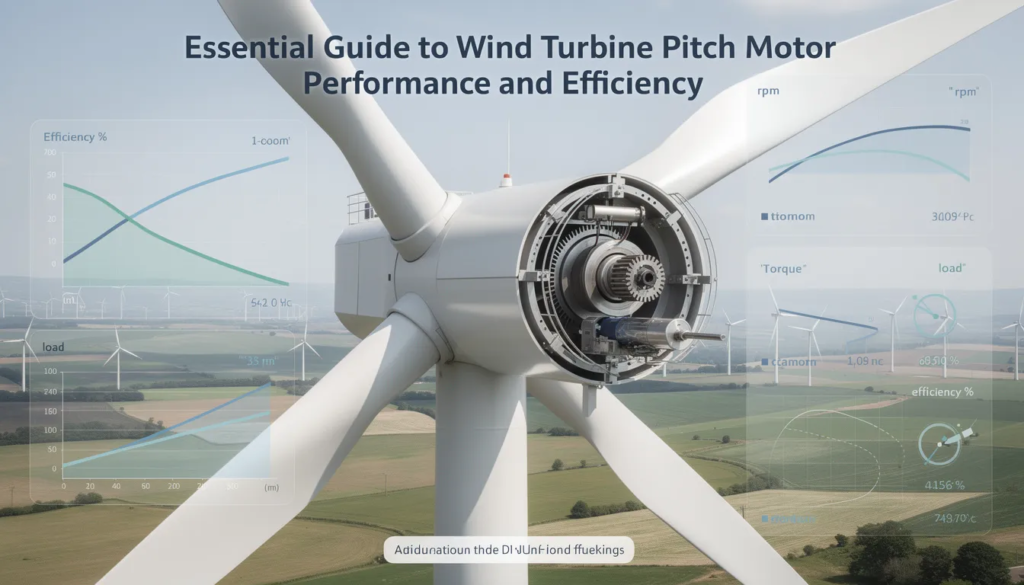

The efficiency of wind turbines depends heavily on wind speed, wind direction, and air density. Wind sensor coupled with control electronics monitors these variables to optimize turbine operation. When wind speed increases, the turbine’s control systems adjust the blade pitch and rotor yaw mechanism to maintain efficient operation and protect the turbine from damage due to excessive wind resistance. These systems help the turbine generate or produce electricity efficiently. However, the efficiency of wind turbines can decrease over time due to factors like dust accumulation on blades, which can affect their aerodynamic performance.

Modern wind turbines are designed to maximize wind energy capture by operating at a high-speed rotation suitable for generating electricity efficiently. The rotor blades are aerodynamically shaped to lower blade bending stresses, thus their wind resistance is minimized, allowing for longer blade life and better performance. The rotor blades of a wind turbine work like an airplane wing, creating lift and drag as wind flows across them.

For further technical insights, visit the American Wind Energy Association and explore detailed resources on wind energy technologies at the U.S. Department of Energy Wind Program.

Types of Wind Turbines

There are two primary designs of wind turbines: horizontal axis wind turbines (HAWTs) and vertical axis wind turbines (VAWTs). Small wind turbines are defined as machines with a power capacity of up to 100 kilowatts, typically used for off-grid or remote applications. In contrast, larger turbines are being developed to generate more electricity and are commonly used in wind farms. The largest operating wind turbines have an electric-generating capacity of about 15,000 kilowatts (15 megawatts).

Horizontal Axis Wind Turbines

Conventional horizontal-axis turbines are the most common type used in large wind farms and offshore wind turbines. These turbines are typically three-bladed, with the blades mounted on a tall tower, allowing them to access higher wind speeds and less turbulent winds. The horizontal axis design features a main rotor shaft aligned with the wind flow, which enables high-speed rotation and efficient conversion of wind energy into mechanical energy. Horizontal-axis wind turbines (HAWT) have blades similar to airplane propellers and commonly have three blades. Air flow patterns around the tower and blades are critical for maximizing turbine efficiency, as proper placement and alignment help optimize energy capture.

Large turbines generally use direct drive generators, which reduce mechanical complexity and improve reliability. The rotor yaw mechanism, guided by a wind sensor that detects wind direction, allows the turbine to rotate and face the incoming wind, optimizing orientation and energy capture. Horizontal-axis wind turbines are widely used in utility grid-connected wind power plants due to their high efficiency and scalability.

Vertical Axis Wind Turbines

Vertical axis wind turbines, such as the Darrieus wind turbine, have rotor blades arranged vertically around the main shaft. The Darrieus turbine is a subtype of vertical axis wind turbines, characterized by its curved or straight blades and efficient aerodynamic design. Darrieus turbines can use three or more blades, which improves rotor solidity and reduces torque ripple, enhancing reliability and efficiency.

Darrieus wind turbines, also known as ‘eggbeater’ turbines, are a type of vertical-axis wind turbine that have good efficiency but produce large torque ripple. This design allows the turbine to capture wind from any direction without needing a rotor yaw mechanism. Darrieus turbines have a flat torque curve and lower blade speed ratio, which helps reduce torque ripple and mechanical stresses.

Although vertical-axis wind turbines are less common than horizontal-axis turbines, they are suitable for specific applications like rooftop-mounted turbine towers in urban environments, where building structures can redirect airflow to enhance wind speeds. Savonius wind turbines, another VAWT subtype, are often used on buses and vans for mobile power generation. Savonius wind turbines are drag-type devices that are always self-starting if they have at least three scoops. The vertical axis design also lowers blade bending stresses, thus their wind resistance is optimized for turbulent winds commonly found near buildings.

Wind Turbine Components

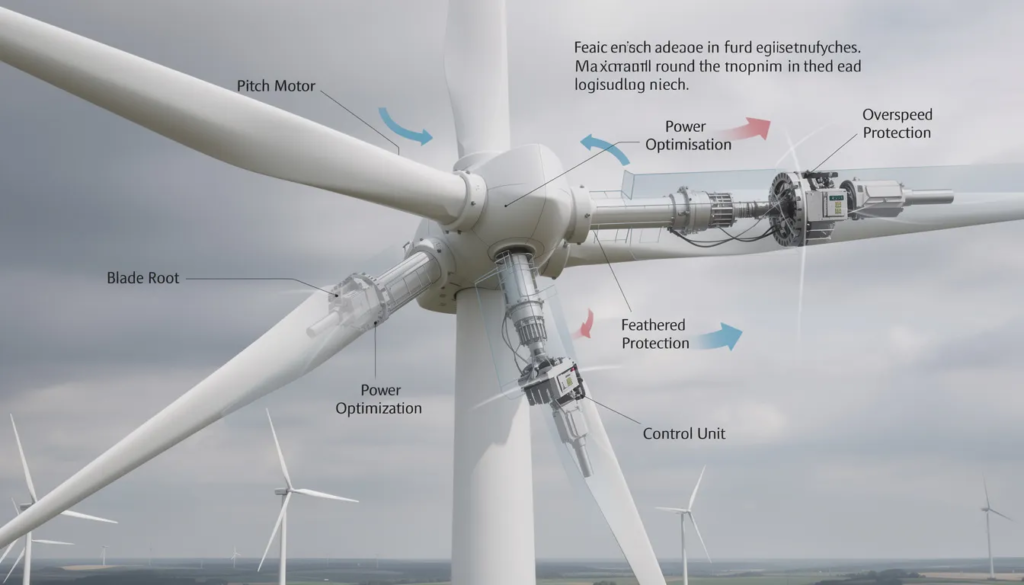

Wind turbines are sophisticated machines made up of several essential components, each playing a critical role in harnessing wind’s kinetic energy and converting it into usable electrical energy. At the heart of every wind turbine is the rotor, which consists of the blades and the hub. The rotor captures the kinetic energy from the wind and transforms it into mechanical energy as the blades spin.

This mechanical energy is transferred to the nacelle, the central housing unit perched atop the tower. Inside the nacelle, you’ll find the gearbox, generator, and advanced control systems. The gearbox increases the rotational speed from the rotor to a level suitable for the generator, which then converts the mechanical energy into electrical energy. Control systems within the nacelle monitor wind conditions and turbine performance, ensuring optimal operation and safety.

Supporting the entire structure is the tower, which elevates the rotor and nacelle to heights where wind speeds are higher and more consistent. The foundation anchors the wind turbine securely to the ground, providing stability even in strong winds. Understanding these components is vital for anyone involved in the design, installation, or maintenance of wind turbines, as each part contributes to the overall efficiency and reliability of converting wind energy into clean power.

Wind Farms and Wind Power Plants

Wind farms consist of multiple wind turbines installed in locations with favorable wind resource assessment. These large wind turbine installations, both onshore and offshore, are designed to generate significant amounts of electrical energy for the electric grid. Offshore wind turbines benefit from higher and more consistent wind speeds, which translates to maximum wind energy capture and increased power output. Ideal wind farm locations are often in remote areas, complicating electricity transmission to urban centers.

Small wind turbines are defined by the American Wind Energy Association as those typically producing less than 100 kilowatts of power. These turbines are often used for residential or small commercial applications and can be installed on rooftops or small towers. Some small wind turbines are specifically designed as a fifty-watt generator for portable or off-grid applications, such as boats and caravans, making them ideal for small-scale, remote, or mobile renewable energy needs.

Small wind turbines can be used for various applications, including powering homes, telecom towers, and rural schools. The main cost of small wind turbines is the purchase and installation process, which averages between $48,000 and $65,000 per installation. Despite their smaller size, they contribute to local renewable energy generation and reduce reliance on the utility grid.

Wind farms play a critical role in lowering greenhouse gases by replacing fossil fuel-based power plants with clean wind power. The integration of wind power plants into the electric grid requires advanced control systems to manage the variable nature of wind energy and ensure a stable electricity supply.

Wind Turbine Maintenance

Maintaining wind turbines is essential for ensuring they operate efficiently and reliably over their lifespan. Regular maintenance routines include inspecting and replacing worn or damaged parts, lubricating moving components, and thoroughly checking the electrical and control systems that manage turbine performance. These tasks help prevent unexpected breakdowns and keep the turbines running smoothly. Wind turbines need regular maintenance to stay reliable and available for energy generation 98% of the time. Wind turbines are designed to withstand various environmental loads and must be structurally sound to operate effectively over their lifespan.

Wind turbine maintenance is typically performed by skilled technicians, either on-site at the wind farm or in specialized workshops. The frequency and complexity of maintenance can vary depending on the size and type of wind turbine, as well as the specific environmental conditions at the installation site. While maintenance does represent an ongoing cost, it is a worthwhile investment—proactive care extends the life of wind turbines, reduces downtime, and ensures maximum energy production. Effective maintenance of control systems is particularly important, as these systems are responsible for monitoring wind conditions and adjusting turbine operation for optimal performance.

Environmental Impact

Wind turbines offer a significant environmental advantage over traditional energy sources, as they generate electricity without emitting greenhouse gases or other pollutants. By relying on wind power instead of fossil fuels, wind farms help combat climate change and reduce the overall carbon footprint of electricity generation. Additionally, wind turbines use little water compared to fossil fuel energy sources, further enhancing their environmental benefits. Wind turbines are one of the lowest-cost sources of renewable energy, alongside solar panels. Using wind power also enhances a nation’s energy security and reduces dependence on fossil fuel imports.

However, the installation and operation of wind turbines can have localized environmental impacts. For example, wind turbines may pose risks to birds and bats, and their presence can alter the visual landscape. Wind turbines can pose a threat to wildlife, particularly birds, although their impact is relatively small compared to other human-related causes of bird mortality.

Some individuals find the visual impact of large wind turbines unappealing and are disturbed by noise from rotating blades. Wind turbines can have a negative visual impact on landscapes, leading to public opposition in some areas.

To address these concerns, wind farm developers conduct thorough environmental assessments before construction and implement measures such as careful site selection, turbine placement, and the use of technologies designed to minimize wildlife collisions. Noise-reducing features and thoughtful design choices, like using taller towers and larger blades, can also help reduce the number of turbines needed and lessen visual impact. By balancing energy production with environmental stewardship, wind turbines continue to be a leading solution for clean, sustainable power.

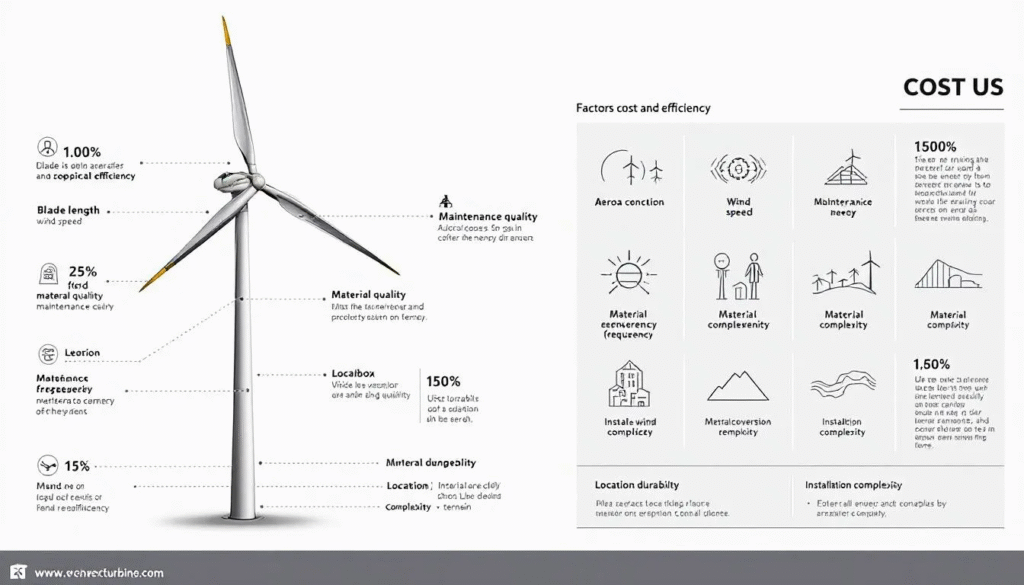

Factors Affecting Wind Turbine Cost and Efficiency

Wind farms play a critical role in lowering greenhouse gases by replacing fossil fuel-based power plants with clean wind power. The integration of wind power plants into the electric grid requires advanced control systems to manage the variable nature of wind energy and ensure a stable electricity supply. The levelized cost of energy (LCoE) is a key metric used to evaluate the economic viability of wind energy projects.

Efficient operation depends on precise wind resource assessment, which evaluates wind speeds, wind velocity, and wind direction at a potential site. Building generally redirects wind flow, creating turbulent winds that can reduce turbine efficiency and increase mechanical wear. Therefore, tall towers are used to elevate turbines above obstacles and access smoother, steadier wind flow. Understanding local air flow patterns is crucial for optimal turbine placement, as it helps maximize energy capture and minimize turbulence-related losses. Wind power density (WPD), a measure of the wind energy available at any location, is also a critical factor in determining the economic feasibility of wind projects.

Control electronics and wind sensors are vital for adjusting turbine parameters in real-time, optimizing power output while minimizing wear and tear. The use of direct drive generators and advanced rotor blade designs further improves the reliability and lifespan of modern wind turbines. Air pressure differences across the blades are harnessed to improve aerodynamic efficiency and enhance the conversion of wind energy into electricity.

Future of Wind Energy

The future of wind energy is bright, driven by ongoing technological advancements and a growing global commitment to renewable energy. One of the most exciting trends is the development of larger and more efficient wind turbines, capable of capturing more wind energy at a lower cost per unit of electricity produced. These modern wind turbines are designed to operate at higher wind speeds and with greater reliability, making wind power increasingly competitive with other energy sources.

Offshore wind energy is also gaining momentum, as offshore wind farms can take advantage of stronger and more consistent wind speeds while minimizing visual and land-use impacts. Innovations such as floating wind turbines are opening up new possibilities for harnessing wind energy in deeper waters, where traditional fixed foundations are not feasible. Offshore wind energy projects have significantly higher installation costs compared to onshore projects.

As demand for clean energy continues to rise, wind turbines will play an ever more important role in the global energy mix. Advances in materials, control systems, and turbine design will further improve efficiency and reduce costs, helping wind energy reach its full potential as a cornerstone of sustainable, renewable energy worldwide.

Conclusion: Wind Turbine Technology and Its Role in Renewable Energy

Wind turbines are a cornerstone technology in the pursuit of renewable energy, offering a sustainable way to generate electricity by harnessing wind energy. Whether through large horizontal-axis wind turbines in expansive wind farms or small vertical-axis wind turbines on rooftops, wind power continues to expand as a clean alternative to conventional energy sources.

By understanding how wind turbines work, the differences between turbine types, and the factors influencing wind turbine cost and efficiency, stakeholders can better appreciate the role of wind power in reducing greenhouse gases and promoting a greener future. Industry leaders like Retek Industrial continue to innovate in this space, enhancing turbine performance and reliability.