Wind turbine pitch motors play a crucial role in the efficient operation of wind turbines, directly influencing the performance and reliability of these machines. Wind turbine pitch motors are a type of electric motor specifically designed to control the angle of the turbine blades within the pitch system, ensuring optimal power generation and protecting the turbine structure under varying wind conditions.

In the wind industry, the pitch system, which includes the pitch motors, is essential for adjusting the angle of turbine blades to optimize power generation and protect the turbine structure under varying wind conditions. This article explores the function, importance, and technical aspects of wind turbine pitch motors, helping customers and industry professionals learn more about this critical component.

Introduction to Wind Energy

Wind energy has become a cornerstone of the global shift toward renewable power, offering a clean, sustainable alternative to fossil fuels. By harnessing the natural movement of air, wind turbines convert kinetic energy into electrical power, reducing greenhouse gas emissions and supporting energy independence. The wind industry continues to grow rapidly, driven by advancements in technology and increasing demand for reliable, eco-friendly energy sources. As more customers and communities seek to reduce their carbon footprint, wind energy stands out as a proven solution for generating power efficiently and sustainably.

Wind Turbines Overview

Wind turbines are sophisticated machines designed to capture the energy of moving air and transform it into usable electricity. Each turbine consists of a set of blades mounted on a rotor, which spins when wind passes over the blades. This rotational motion is transferred through a shaft to a generator, where it is converted into electrical power. The efficiency and reliability of a wind turbine depend on its ability to adapt to changing wind conditions, maintain optimal speed, and protect its structure from extreme events. Modern wind turbines are engineered to maximize energy capture while minimizing maintenance needs, making them a vital part of the renewable energy landscape.

Components of a Wind Turbine

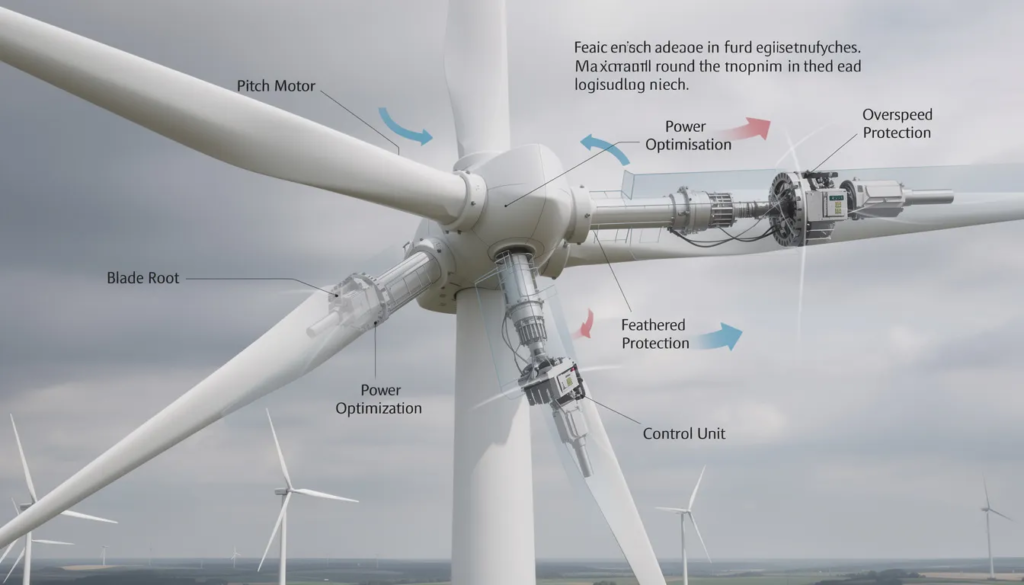

A wind turbine is made up of several key components, each playing a critical role in the power generation process. The rotor, which includes the blades and hub, is responsible for capturing wind energy. The blades are aerodynamically designed to maximize efficiency, while the hub connects them to the main shaft. The shaft transfers rotational energy to the generator, which produces electrical power.

The pitch system, including the pitch motors, adjusts the angle of the blades to optimize performance and protect the turbine during high winds. Hydraulic and electric systems are used for pitch control, with electric systems often employing DC motors for their responsiveness and reliability. Pitch control systems comprise less than 3% of the capital expense associated with a wind turbine. Other essential parts include the nacelle, which houses the generator and control systems, and the tower, which elevates the turbine to capture stronger winds. Together, these components ensure the turbine operates safely, efficiently, and reliably at any site or location.

What Are Wind Turbine Pitch Motors?

Wind turbine pitch motors are specialized electric motors designed to control the pitch, or angle, of the blades on a wind turbine. The pitch system adjusts the blade angle relative to the wind to maximize energy capture and maintain the safety and stability of the turbine. By changing the blade pitch, the motor can regulate the rotor speed and power output, ensuring the turbine operates within its design limits. Pitch motors are equipped with a secondary backup Resistance Temperature Detector (RTD) to prevent nuisance tripping and enhance reliability. The pitch motors require an independent backup power supply to ensure fail-safe operation in case of grid power failure.

These motors are typically mounted on the turbine hub, directly connected to the blade shaft. In the pitch system, the pitch motor has its place as the key actuator responsible for adjusting blade angles, fitting precisely within the overall pitch control architecture. Their design must accommodate the harsh conditions at the turbine site, including exposure to wind, weather, and mechanical stresses. Pitch motors are adapted to the demanding operation in wind turbine installations and have been tested under extreme climatic conditions. As a result, pitch motors are built to withstand these challenges while providing reliable and precise control.

The Role of Pitch Motors in Wind Turbines

The primary function of pitch motors is to adjust the turbine blades’ angle to optimize the rotor’s aerodynamic efficiency. When wind speeds change, the pitch system reacts by altering the blade pitch to capture the maximum amount of wind energy or to reduce the load on the turbine during high winds. The difference in air pressure across the blades is what generates lift and causes the blades to rotate, and pitch motors help manage this difference to ensure efficient operation. The ability to control blade angles precisely contributes to grid stability by enabling smoother power regulation.

This process is critical for maintaining the balance between power production and the mechanical integrity of the turbine. By quickly changing the blade angle, pitch motors help prevent damage to the structure and other components, extending the machine’s lifespan and reducing maintenance needs. The pitch system can also ‘feather’ the blades to prevent damage to the machine when wind speeds are too high.

Importance of Reliability and Speed in Pitch Motors

Reliability is paramount for pitch motors because they operate continuously and must respond rapidly to changing wind conditions. A failure in the pitch system can lead to inefficient power generation or, worse, structural damage to the turbine.

The speed at which pitch motors adjust the blade angle directly impacts the turbine’s ability to respond to sudden wind gusts or changes in direction. High-speed pitch motors enable the turbine to maintain optimal performance and protect itself from extreme conditions, ensuring consistent power output and operational safety.

Design Considerations for Wind Turbine Pitch Motors

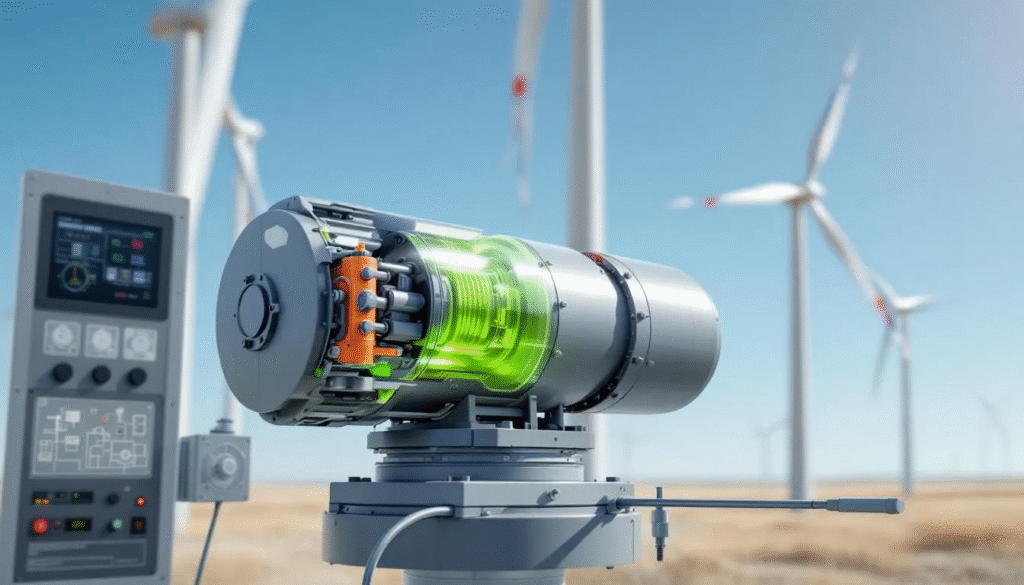

Wind turbine pitch motors are designed with several critical factors in mind. They must be robust enough to withstand the mechanical loads and environmental conditions at the turbine site. This includes resistance to temperature variations, moisture, and mechanical vibrations. The design of pitch motors reflects many years of experience with pitch applications and mechanical engineering.

The electrical components of the motor are engineered to provide precise control and efficient operation. Precision sealed bearings in pitch motors are designed to operate under demanding conditions, providing smooth and reliable movement. The motor’s structure is optimized to minimize weight while maintaining strength, which is essential for the dynamic environment of the wind turbine hub. The AC synchronous motors stand out for their high power density, making them a preferred choice in many applications. Pitch motors from Warfield Electric come with an extra layer of ground insulation placed behind the field coils, which enhances the motor’s resistance to electrical stress and environmental factors.

Manufacturers like Retek Motion also consider the ease of maintenance and replacement of pitch motors, as minimizing downtime is vital for customers relying on continuous wind energy production. Modern pitch motor designs reduce the need for reserve capacity to a certain extent, improving efficiency and independence compared to traditional systems. The one-year warranty included with Warfield Electric’s pitch motors gives customers peace of mind and ensures they are covered in the event of any unexpected issues.

How Pitch Motors Enhance Wind Energy Efficiency

By maintaining the optimal blade angle, pitch motors directly contribute to the overall efficiency of the wind turbine. Proper pitch control maximizes the aerodynamic performance of the blades, allowing the turbine to capture more wind energy and convert it into electrical power effectively.

Additionally, pitch motors help reduce mechanical stress on the turbine, which can otherwise lead to wear and tear or unexpected failures. This not only ensures the longevity of the turbine but also improves the reliability of power generation, benefiting both operators and customers.

Challenges and Solutions in Pitch Motor Technology

One of the main challenges in pitch motor technology is ensuring that the motor can operate flawlessly under diverse and sometimes extreme conditions. To address this, manufacturers develop pitch motors with advanced materials and protective coatings that enhance durability. The inner case of pitch motors is treated to enhance resistance to moisture and contaminants, promoting long-term performance.

Another challenge is the integration of pitch motors with the turbine’s control system. Modern pitch systems use sophisticated sensors and control algorithms to provide real-time adjustments, requiring motors that can respond quickly and accurately. Feedback from sensors like encoders provides continuous position data to the control system for precise adjustments of the blade angles. In an electric pitch system, the control system processes sensor data to adjust each blade’s angle in real time, ensuring optimal performance and safety.

Ongoing innovations in motor design and control technology continue to improve the performance and reliability of pitch motors, helping the wind industry meet the growing demand for clean and efficient wind energy.

Pitch System Maintenance

Maintaining the pitch system is essential for ensuring the long-term reliability and efficiency of wind turbines. Regular inspections and servicing of pitch motors and related components help detect wear, electrical issues, or mechanical stress before they lead to costly downtime. Proactive maintenance includes checking the condition of the motor, lubricating moving parts, and updating control software to respond to changing wind conditions. By keeping the pitch system in optimal condition, operators can quickly address potential problems, reduce the risk of unexpected failures, and extend the lifespan of both the pitch motor and the entire turbine. Pitch subsystems account for 23% of all downtime associated with wind turbines, highlighting the importance of regular maintenance.

Economic Benefits of Wind Energy

Investing in wind energy offers significant economic advantages for both operators and communities. Wind turbines provide a cost-effective source of power, with low operating expenses and minimal fuel costs compared to traditional energy sources. The reliability and efficiency of modern turbines, supported by advanced pitch motors, help reduce maintenance costs and increase uptime, ensuring a steady flow of electrical power.

Wind energy projects also create jobs in manufacturing, installation, and maintenance, boosting local economies. Over time, the use of wind power can lead to substantial savings on energy bills and provide a stable, long-term return on investment. By choosing wind energy, customers not only support a cleaner environment but also benefit from the financial rewards of a sustainable power solution.

Conclusion: The Critical Role of Wind Turbine Pitch Motors

Wind turbine pitch motors are indispensable components in the operation of wind turbines. They enable precise control of turbine blades, ensuring that the rotor captures wind energy efficiently while protecting the machine from damage. The reliability, speed, and design of pitch motors directly affect the performance and safety of wind turbines, making them a focus for innovation and quality in the wind industry. The advanced features and options available with Warfield Electric’s pitch motors ensure their durability and performance.

Customers and operators looking to maintain or upgrade their turbines should understand the importance of the pitch system and select pitch motors designed to meet the specific conditions of their site. Reliable pitch motors help reduce costly downtime, which can otherwise last for more than a day, thus minimizing maintenance costs and ensuring the continued efficiency and reliability of their wind energy assets. To learn more about wind turbine pitch motors and how they can enhance your wind energy projects, read further industry resources such as WindEurope, American Wind Energy Association, and National Renewable Energy Laboratory.

For expert solutions and tailored products, consider consulting with Retek Motion, a trusted provider in the field of wind turbine pitch motors and related components. Customers are welcome to request repairs or spare parts as needed—Retek Motion responds promptly to all requests. Warfield Electric offers both new pitch motors and remanufactured pitch motors and yaw motors with enhanced features.