Introduction to Wind Energy

Wind converters are integral to the modern wind energy landscape, playing a crucial role in transforming wind power into reliable electrical energy. Wind energy has emerged as a cornerstone of the world’s transition to renewable energy, providing a clean and sustainable alternative to fossil fuels. The wind power industry has seen remarkable growth in recent years, fueled by technological advancements, decreasing costs, and a global push for cleaner sources of electricity. Modern wind turbines are at the heart of this transformation, with larger wind turbines and expansive wind farms being developed to meet the increasing demand for electrical power.

Integrating wind power into the power grid is essential for delivering a stable and efficient supply of electricity. Companies like Retek Industrial Co.,Limited and ABB play an important role in this process, developing advanced power converters and control systems that optimize energy production and reduce the overall cost of wind energy. Innovations in rotor blade design, generator efficiency, and system integration are making wind energy more accessible and affordable than ever before.

As investment in wind energy continues to rise, the development of new technologies and solutions is driving the industry forward. The ongoing evolution of wind turbines, power converters, and supporting infrastructure ensures that wind energy will remain a key player in the global energy market, helping to meet the world’s growing electricity needs while supporting a sustainable future.

For more detailed insights into wind power technology, visit the Global Wind Energy Council or explore Renewable Energy World for the latest industry updates. Additionally, the International Renewable Energy Agency (IRENA) offers comprehensive resources on renewable energy advancements.

Types of Wind Turbines

Wind turbines come in several types, each designed to harness wind energy efficiently in different environments and applications. The most common are horizontal-axis wind turbines (HAWT), which dominate wind farms around the world due to their high efficiency and proven reliability. These turbines are easily recognizable by their large rotor blades and tall towers, and are typically used in utility-scale wind farms to generate significant amounts of electricity.

Vertical axis wind turbines (VAWT), while less common, offer unique advantages such as reduced noise and lower visual impact, making them suitable for urban and residential settings. Wind turbines in urban environments can handle turbulent and changing wind patterns caused by buildings. The choice between HAWT and VAWT depends on factors like wind speed, site conditions, and the intended application. Darrieus turbines are more efficient than Savonius types but may require an external starting mechanism. Savonius turbines, on the other hand, are less efficient but are simple, inexpensive, and can start from any wind speed. HAWTs are common for large-scale power generation, whereas VAWTs are often suited for urban settings due to their omnidirectional nature.

Utility-scale wind turbines are specifically designed to deliver large-scale power generation, supporting the needs of the grid and enabling the development of extensive wind farms. Utility-scale wind Farms power the electrical grid for large populations. Meanwhile, smaller wind turbines are used for localized applications, such as residential or commercial electricity generation. The ongoing development of new wind turbine technologies—including floating turbines and those built with advanced materials—continues to expand the range of suitable applications for wind energy, ensuring that turbines can be designed to meet the unique needs of different industries and environments.

Offshore Wind Turbines

Offshore wind turbines are playing an increasingly important role in the wind energy industry, offering access to stronger and more consistent winds than many onshore locations. These turbines are installed in marine environments, often far from shore, and require specialized equipment and techniques for installation, such as large ships and cranes. Offshore installations of wind turbines are ideal for consistent, strong winds in large bodies of water. Offshore wind turbines are engineered to withstand harsh marine conditions, including saltwater corrosion and powerful storms.

The development of offshore wind farms is accelerating in regions like Europe, Asia, and North America, where space for onshore wind farms may be limited. Offshore wind turbines offer several advantages, including reduced visual and noise impact, as well as higher energy production due to the favorable wind conditions at sea. However, they also present unique challenges, such as higher installation and maintenance costs and the need for robust infrastructure.

To address these challenges, companies like Retek Industrial Co.,Limited and ABB are developing advanced power converters, control systems, and other solutions specifically designed for offshore applications. These technologies support the reliable operation of offshore wind turbines, helping to unlock new opportunities for wind energy and drive the global transition to renewable power.

Introduction to Wind Converters

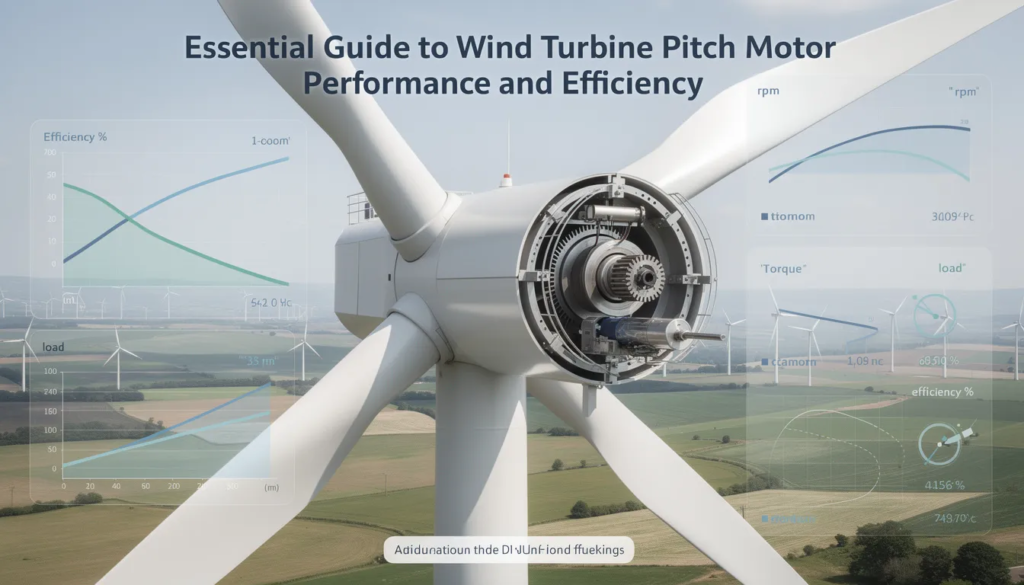

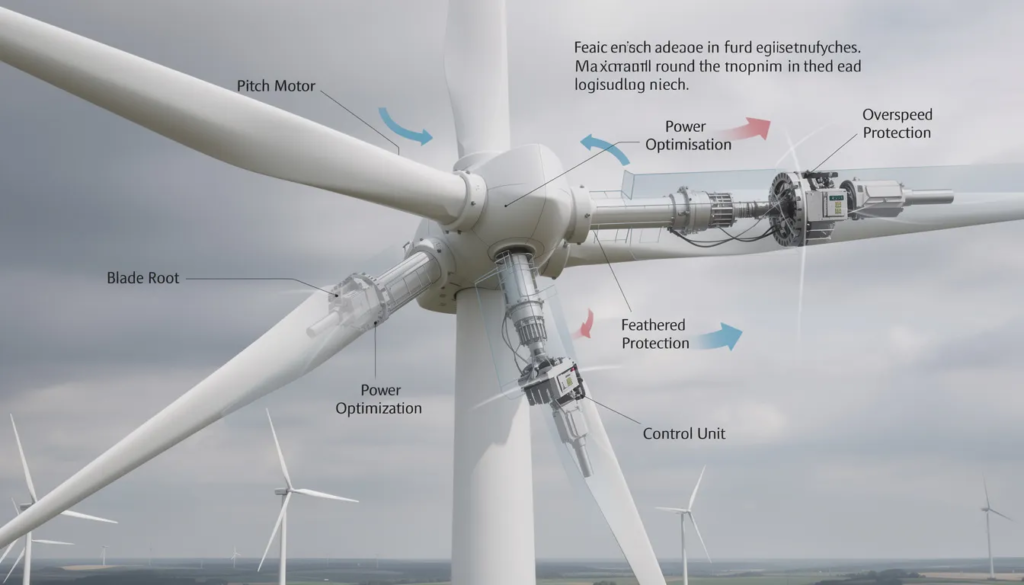

Wind converters play an important role in the generation of electrical power from wind energy. The controller within a wind converter manages the conversion process, ensuring efficient operation and communication with other system components. These devices are essential components in wind turbines, converting the mechanical energy produced by the rotor blades into electricity that can be fed into the power grid. Wind turbine blades create a difference in air pressure that generates lift and causes the blades and connected shaft to spin.

Electrical subsystems in large-scale turbines can achieve an efficiency of 93% to 98%. Wind power converters are mainly used together with generators to optimize energy production. Wind converters are primarily categorized as horizontal-axis (HAWT) and vertical-axis (VAWT) types. Partial-Scale Converters (PSFC) connect only the rotor to the grid through the converter, reducing costs but limiting output.

As wind power continues to grow as a sustainable energy source worldwide, the development and deployment of advanced wind power converters have become crucial to meet the increasing demand for reliable and efficient energy solutions.

The Role of Wind Converters in Wind Turbines

In a wind turbine system, the converter serves as the interface between the generator and the grid. It converts the variable frequency and voltage generated by the turbine’s rotor into stable electrical power compatible with the grid’s requirements, regulating the output from the stator to control voltage amplitude, frequency, and phase for optimal grid integration. This conversion process ensures that the electricity produced can be reliably integrated into the power grid, regardless of fluctuations in wind speed or turbine operation. Wind converters help achieve Variable Speed Constant Frequency (VSCF) for better power generation efficiency. The flexibility offered by wind converters allows wind turbines, including larger wind turbines and offshore wind turbines, to operate efficiently in a variety of conditions.

Types of Wind Power Converters and Their Applications

Wind power converters vary in design depending on the type and scale of the wind turbine system. Utility-scale wind turbines, which constitute the majority of installed wind farms, typically use sophisticated power converters designed to handle high power levels and harsh environments. These converters are built with robust hardware and advanced software solutions to ensure continuous operation and minimize failure events.

ABB offers wind turbine converters for utility-scale wind turbines. ABB’s MV wind converters are designed for utility-scale wind turbines and will have ratings of up to 20 MW and beyond. Full-Scale Converters (FSFC) connect both the stator and rotor through the converter, providing greater control and flexibility. Wind converters are designed to fulfill strict grid codes and can be air-cooled or air/water-cooled for harsh environments.

To address the diverse requirements of different wind energy applications, manufacturers offer a comprehensive portfolio of wind power converters, featuring a range of high-power, high-efficiency components tailored for both onshore and offshore systems.

For offshore wind turbines, which face more demanding conditions due to their location, converters are designed to be compact and flexible, providing reliable performance while reducing maintenance needs. The higher voltage level of medium voltage converters results in lower currents in the electrical drivetrain. Medium voltage converters enable a higher penetration of renewable energy into the grid without compromising stability.

The new generation of medium voltage converters has built-in intelligent software and digital features for remote monitoring and diagnostics. These converters can deliver an estimated 33% uplift in power with the same number of components as their lower power predecessors. The combination of converter technology and turbine design enables these systems to deliver optimal power output and durability.

Technological Advancements and Development in Wind Converter Systems

The wind energy market has seen significant advancements driven by research and development efforts from leading companies like Retek Industrial Co.,Limited and ABB. Engineers continually work to develop new technologies and improve existing hardware and software components to create more efficient and cost-effective wind converters. This includes creating advanced control algorithms and simulation models to improve wind converter performance. Medium voltage converters help wind park operators maintain profitability by offering higher efficiency and lower total cost of ownership. The new generation of medium voltage converters features high-efficiency integrated gate-commutated thyristor technology.

Medium voltage converters have a more compact footprint and are lighter in weight compared to traditional converters. These innovations include enhanced controllers that simulate and manage turbine operation, ensuring that the system meets grid requirements and adapts to variable wind conditions.

Testing and validation are critical steps in the development process, enabling companies to deliver products that meet customer expectations and industry standards. The integration of data analytics and flexible control systems further supports the evolution of wind converter technology, making it suitable for a wide range of industrial applications.

Harsh Environments

Wind turbines are often deployed in harsh environments, from arid deserts to icy Arctic regions, where extreme temperatures, high winds, and corrosive atmospheres can impact their performance and longevity. To ensure reliable operation, the design and construction of wind turbines must account for these demanding conditions. This includes the use of specialized materials and protective coatings to guard against corrosion, as well as robust engineering to withstand intense wind loads and temperature fluctuations.

Power converters and control systems are also engineered to operate reliably in harsh environments, with features such as advanced cooling systems, vibration resistance, and humidity protection. The development of new technologies—like condition monitoring and predictive maintenance systems—further enhances the ability of wind turbines to operate efficiently and reliably, even in the most challenging locations.

Companies like Retek Industrial Co.,Limited are at the forefront of developing solutions that support wind turbines in harsh environments, ensuring that wind energy can be harnessed wherever it is needed. As the use of wind power expands into more extreme settings, ongoing innovation in turbine and converter design will be essential for maintaining high performance and minimizing downtime.

Control and Monitoring Systems

Control and monitoring systems are essential for maximizing the performance and reliability of wind turbines. These systems use advanced sensors, software, and communication technologies to provide real-time data on turbine operation, including power output, rotor speed, and wind direction. This information enables operators to remotely control and optimize turbine performance, ensuring efficient energy generation and quick response to changing wind conditions.

The development of sophisticated control and monitoring systems, including advanced algorithms and machine learning techniques, is driving further improvements in wind turbine efficiency and reliability. Predictive maintenance software and SCADA (Supervisory Control and Data Acquisition) systems allow for early detection of potential issues, reducing downtime and maintenance costs.

Industry leaders like Retek Industrial Co.,Limited and ABB are continuously developing new control and monitoring solutions to support the growth of wind energy. By integrating cutting-edge software and hardware, these systems help wind turbines operate at peak performance, supporting the ongoing development and expansion of wind power worldwide.

Benefits of Advanced Wind Converters

The benefits of modern wind converters extend beyond efficient power generation. By providing stable and high-quality electrical power, these converters support the integration of wind energy into the grid, facilitating the growth of wind farms worldwide. Their design allows turbines to operate reliably over long periods, reducing downtime and maintenance costs. These advantages help customers optimize wind energy output, improve turbine performance, and maximize return on investment by ensuring reliable operation tailored to their specific project needs.

Moreover, the flexibility and compact nature of these converters make them ideal for various turbine sizes and configurations, including those installed in harsh environments. This adaptability helps create new opportunities for wind energy deployment, contributing to the future expansion of renewable energy sources.

Future Outlook and Market Trends

As the demand for clean and sustainable energy increases, the wind power market is expected to continue expanding. Investment in wind converter technology will play a key role in this growth, enabling the development of larger wind turbines and more complex wind farm systems. Companies focused on innovation and customer support, like Retek Motio, will be well-positioned to lead the market by delivering advanced solutions that meet evolving grid and industry requirements. A company can leverage advanced wind converter solutions to improve communication and control within its wind energy infrastructure, enhancing operational efficiency and system reliability.

The future of wind energy depends on the continuous improvement of converter systems, combining hardware robustness with intelligent software to optimize turbine performance and maximize electricity generation. By developing flexible and reliable wind converters, the industry can ensure that wind power remains a vital component of the global energy mix.

Conclusion: The Vital Role of Wind Converters in Wind Energy

Wind converters are fundamental to the efficient and reliable operation of wind turbines, transforming wind energy into usable electrical power for the grid. Through ongoing development and technological innovation, these converters enable wind turbines to operate in diverse environments and meet the increasing demands of the wind power market. Ingeteam is the world’s #1 independent supplier of wind power converters with an 8% market share. As the world moves toward a sustainable energy future, wind converters will continue to play an important role in harnessing the potential of wind energy and supporting the growth of renewable power generation worldwide.