Introduction to Wind Energy

- Wind turbine pitch motors are crucial in the wind industry, enabling precise adjustment of turbine blades based on wind speed to generate clean, renewable energy.

- A wind turbine pitch motor is the primary electromechanical actuator responsible for rotating rotor blades around their longitudinal axis. It adjusts the blades’ angle relative to the wind, optimizing energy capture for varying wind speeds and protecting the turbine from damage.

- This guide is intended for wind turbine operators, engineers, and industry professionals seeking to maximize turbine efficiency and reliability through advanced pitch motor solutions.

- The wind energy sector has grown rapidly, with wind turbines becoming more efficient thanks to advancements in pitch motor technology.

- Wind turbine blades capture wind energy by creating a difference in air pressure across their surfaces, producing lift and drag forces essential for rotor movement and converting wind into electric power.

- The pitch system, powered by dependable wind turbine pitch motors, plays a vital role in ensuring optimal turbine performance.

Understanding Wind Turbines

- Wind turbines consist of rotor blades, a hub, and a motor, all working together as a machine that depends on control systems to manage operation and avoid damage.

- The drivetrain includes several shafts—main, high-speed, and low-speed—that connect components like the gearbox and generator, converting rotational energy into electricity. The turbine’s electric motor is built to endure harsh environmental conditions and maintain reliability.

- Wind turbines operate within a specific wind speed range to maximize energy capture.

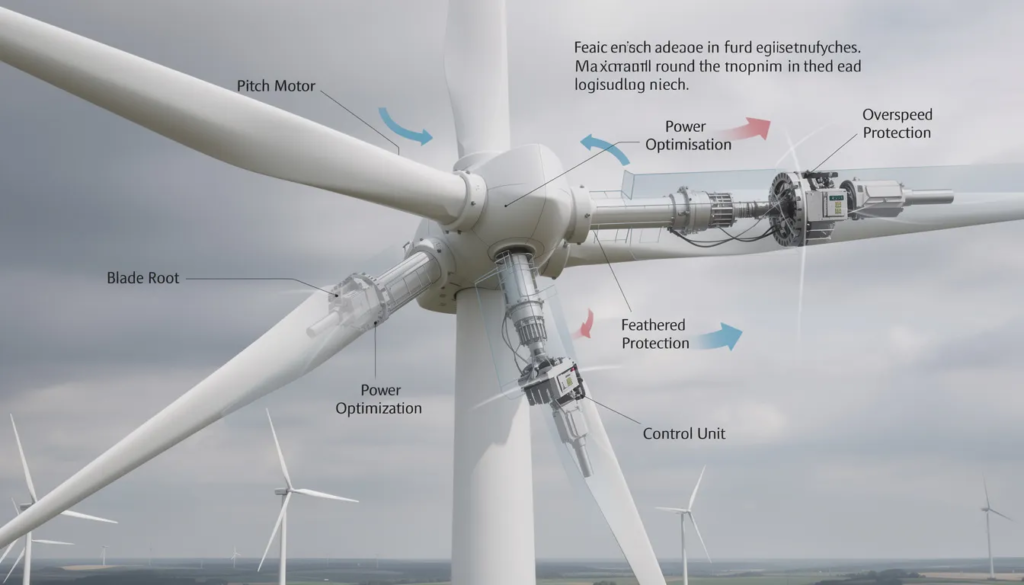

- The pitch control system adjusts the angle of turbine blades to optimize power output and ease structural stress. The wind turbine pitch motor is the primary electromechanical actuator that rotates the rotor blades around their longitudinal axis.

Pitch System Overview

- The pitch system is essential for adjusting the pitch angle of turbine blades and includes parts that require regular maintenance and high-quality replacements.

- It ensures turbine blades are positioned to capture the maximum wind energy.

- Pitch control mechanisms work alongside the turbine’s electric motor and gears.

- This system plays a significant role in maintaining turbine performance and reducing downtime. Pitch control systems account for 23% of all downtime related to wind turbines, underscoring the need for proper maintenance and quality parts.

Pitch Control Mechanisms

- Pitch control mechanisms adjust blade pitch angles in response to changing wind conditions and manage turbine startup by positioning blades when wind speeds reach the required threshold.

- Sensors and software determine the optimal pitch angle for maximum energy capture. The system can also ‘feather’ blades to prevent damage during high winds.

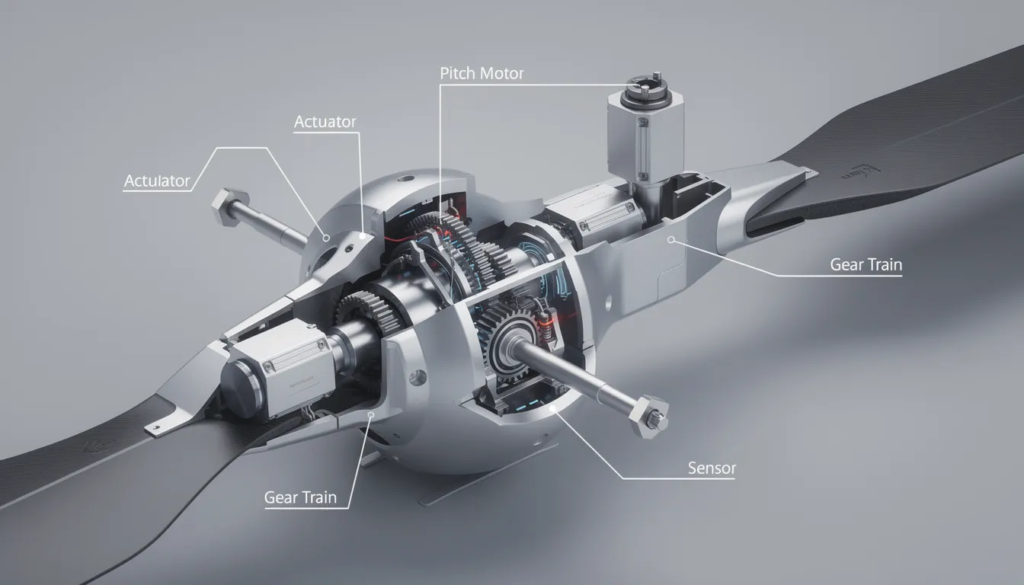

- Pitch motors and actuation systems collaborate to adjust blade pitch. These motors react in real-time to wind turbulence, balancing mechanical loads to reduce fatigue on the tower and bearings. They also include a failsafe holding brake to maintain blade angle when not actively pitching.

- The pitch control mechanism is critical to the reliability and efficiency of wind turbines.

Pitch Motors and Actuation

Baolei Electric Pitch Motor Features

- Baolei Electric‘s wind turbine pitch motors provide precise control over blade pitch angles. They are engineered to perform reliably under demanding conditions and have been tested in extreme climates. Their precision sealed bearings support operation in tough environments.

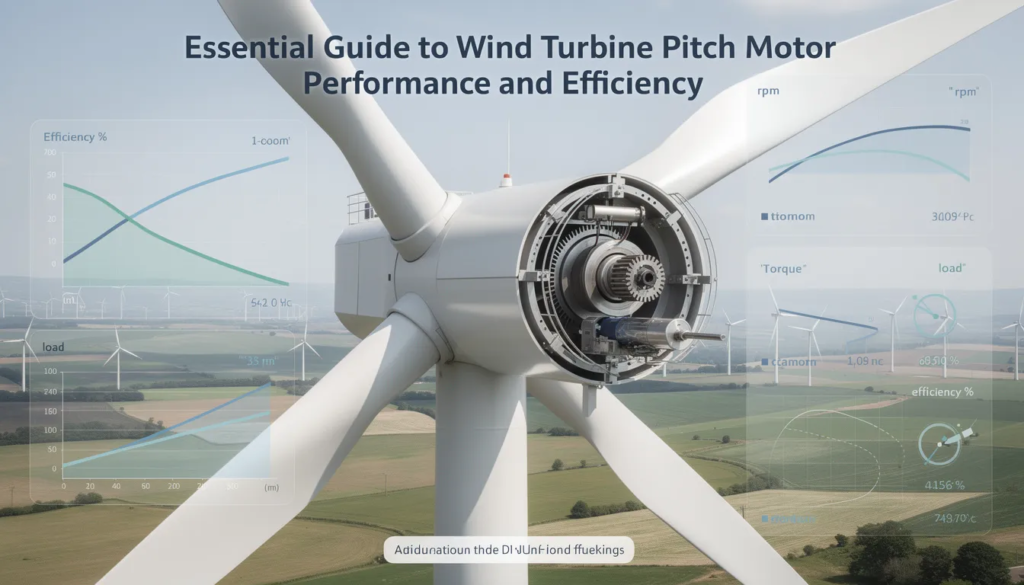

- The pitch motor works with the turbine’s gears and electric motor to adjust pitch angles. The number of reduction stages varies depending on the required reduction ratio. These motors deliver high power density and a broad range of rotational speeds at maximum torque. Additionally, they can include a secondary backup Resistance Temperature Detector (RTD) to prevent nuisance tripping.

Reliability and Maintenance

- Pitch drives are designed for reliability and efficiency, minimizing downtime. Advanced pitch motors can perform Individual Pitch Control (IPC), adjusting each blade independently to handle asymmetric loads.

- The pitch motor is a key component of the pitch system, vital for optimal turbine performance.

Customization and Support

- Baolei Electric offers both new and retrofit pitch motors tailored to various turbine models and operating conditions. Their motors feature enhanced insulation and robust construction for long-term reliability.

Benefits of Optimized Pitch Motors

- Optimized pitch motors from Baolei Electric can boost wind turbine efficiency by increasing energy capture and lowering costs.

- A well-designed pitch motor reduces stress on turbine structures, extending their lifespan.

- These motors withstand extreme weather, ensuring reliability and reducing maintenance expenses.

- Using high-quality pitch motors improves overall wind turbine performance, making them indispensable in the wind industry.

- Comprehensive service options and quality components give customers confidence in their wind turbine operations.

Key Benefits:

- Increased energy capture and reduced operational costs

- Extended turbine lifespan by minimizing structural stress

- Reliable performance in extreme weather conditions

- Lower maintenance expenses

- Enhanced overall wind turbine performance

- Confidence through comprehensive service and quality components

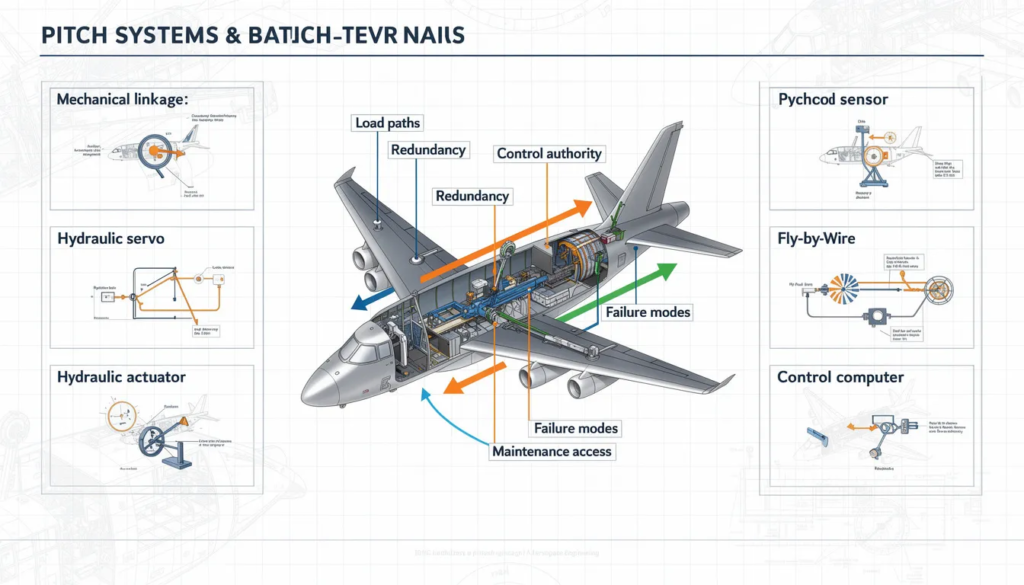

Design and Engineering Considerations for Pitch Systems

- Designing pitch systems involves balancing wind speed, turbine performance, and reliability.

- Engineers must optimize energy capture while minimizing structural stress.

- Advanced materials and technologies, including gears and electric motors, enhance pitch system efficiency and reliability. Independent drive solutions, for example, increase resilience and operational independence compared to traditional mains-fed systems, reducing the need for safety reserves.

- Maintenance and repair considerations are integral to design, ensuring components can be replaced or serviced easily.

Design Considerations:

- Balance between wind speed, performance, and reliability

- Optimization of energy capture and reduction of structural stress

- Use of advanced materials and technologies for efficiency

- Incorporation of independent drive solutions for resilience

- Ease of maintenance and repair

Technological Advances in Wind Turbine Technology

- Recent advances have led to more efficient and reliable pitch systems.

- The use of modern materials and technologies, such as electric motors and gears, has boosted turbine performance.

- New pitch control mechanisms and pitch motors continue to improve efficiency and reliability.

- The wind industry is constantly evolving with innovations aimed at enhancing turbine performance.

Challenges with Wind Turbine Maintenance

- Wind power plant locations affect turbine placement, energy production, and maintenance logistics, which impact operational efficiency and costs. Maintenance can be especially challenging at remote sites.

- Advanced technologies like electric motors and gears help reduce maintenance and repair needs.

- Regular maintenance is essential to keep turbines reliable and efficient, minimizing downtime and maximizing energy capture.

- Developing new maintenance strategies and technologies is vital to improving turbine performance.

The Importance of Quality Components

- Using high-quality components such as pitch motors and gears is key to turbine reliability and efficiency.

- Quality parts reduce downtime and enhance overall turbine performance.

- Component selection must consider wind speed, turbine performance, and reliability.

- High-quality components extend turbine lifespan, lower maintenance costs, and increase energy capture.

Quality Component Benefits:

- Improved reliability and efficiency

- Reduced downtime

- Enhanced turbine performance

- Extended lifespan and lower maintenance costs

- Increased energy capture

Maximizing Efficiency with the Right Solutions

The Role of Advanced Pitch Control

Maximizing wind turbine efficiency depends on the right pitch control solutions—systems engineered to adjust blade angles precisely as wind conditions change. Baolei Electric’s advanced pitch motors are central to this process, ensuring each blade is positioned to capture maximum wind energy. These motors must handle harsh weather, variable wind speeds, and the mechanical stresses of continuous operation in the wind industry.

Performance and Flexibility

Modern pitch systems with high-quality motors offer a broad range of rotational speeds and torque, allowing turbines to perform efficiently across diverse wind conditions. This flexibility not only increases energy capture but also reduces mechanical stress on blades, extending their lifespan and cutting costly repairs. By lowering downtime and maintenance needs, reliable pitch control solutions help reduce operational costs and improve turbine performance.

Customization and Support

Designing and implementing effective pitch control systems requires technical expertise and a deep understanding of the challenges faced by wind turbine operators. Working with experienced manufacturers like Baolei Electric ensures pitch motors and control systems are customized for each installation—whether onshore or offshore, new build or retrofit. These partnerships provide access to the latest advancements in pitch drive technology, including advanced materials and innovative designs that enhance power, range, and reliability.

Reliability and Maintenance

Reliability in pitch motors is critical. When a pitch motor fails, quick repair or replacement is essential to minimize downtime and maintain turbine output. High-quality components and expert support from Baolei Electric help turbines return to service swiftly, protecting both energy production and revenue.

Strategic Investment

Investing in the right pitch control solutions is a strategic choice affecting long-term success and profitability for wind farms. Prioritizing efficiency, reliability, and expert support helps operators maximize returns, lower energy production costs, and contribute to a sustainable energy future.

For those aiming to improve wind turbine performance, connecting with knowledgeable manufacturers like Baolei Electric is the first step. Understanding the vital role of pitch control and making informed decisions about system design and maintenance ensures turbines operate at peak efficiency—capturing more wind energy, reducing environmental impact, and advancing the industry.

Whether starting new projects or upgrading existing turbines, investing in advanced pitch control solutions is a clear choice. With the right systems, wind turbines can deliver reliable, efficient, and cost-effective power generation day after day. To learn more about maximizing efficiency with top wind turbine pitch motor solutions, operators should contact experienced providers like Baolei Electric, who offer the expertise, products, and support needed for success in any wind environment.

Conclusion: Optimizing Wind Turbine Efficiency

- Optimizing wind turbine efficiency is essential for lowering costs and boosting energy capture.

- High-quality pitch motors and pitch systems can greatly enhance turbine efficiency.

- Ongoing innovation is vital for improving wind turbine performance.

- The wind industry must keep evolving to ensure turbines remain reliable and efficient renewable energy sources.

Future of Wind Turbine Technology

- The future holds exciting innovations to improve efficiency and reliability.

- Advanced materials and technologies like electric motors and gears will continue to drive turbine development.

- New pitch control mechanisms and pitch motors will further enhance turbine efficiency and reliability.

- The wind industry will keep evolving, developing technologies to improve turbine performance and reduce costs.