Introduction to Wind Energy and Yaw Motors

Wind energy is a rapidly growing sector, providing clean and renewable electricity to communities worldwide. This article focuses specifically on yaw motors in wind turbines, exploring their critical role in optimizing turbine performance. The scope of this discussion includes the function, selection, and optimization of yaw motors, with a particular emphasis on solutions from Baolei Electric.

The target audience for this article includes engineers, wind energy professionals, and decision-makers involved in the design, operation, and maintenance of wind power plants. Understanding the importance of yaw motors is essential for these stakeholders, as optimizing yaw motors directly impacts wind turbine efficiency, reliability, and maintenance costs.

Yaw motors are essential components in wind power plants, which generate electricity by harnessing wind energy—a clean and renewable resource. Yaw motors are specialized electric motors that play a crucial role in wind turbine operation by enabling the nacelle to rotate and face the wind. Companies like Baolei Electric play a significant role in supplying these critical components to the industry.

Wind turbines convert wind energy into electrical energy through the rotation of the wind turbine rotor. The tower, usually made of tubular steel and assembled in sections, supports the blades and nacelle, raising the turbine to capture more wind efficiently.

A wind vane measures wind direction, which is crucial for positioning the turbine correctly. Sensors on the nacelle monitor wind direction and speed to help control the yaw system.

Wind power is a widely used source of electricity, and wind turbines are key to capturing this energy. The hub, generator, and electronic systems work together inside the turbine to ensure smooth operation and efficient energy production.

By focusing on yaw motors, this article aims to provide actionable insights for optimizing wind turbine performance, reducing operational costs, and supporting the transition to sustainable energy.

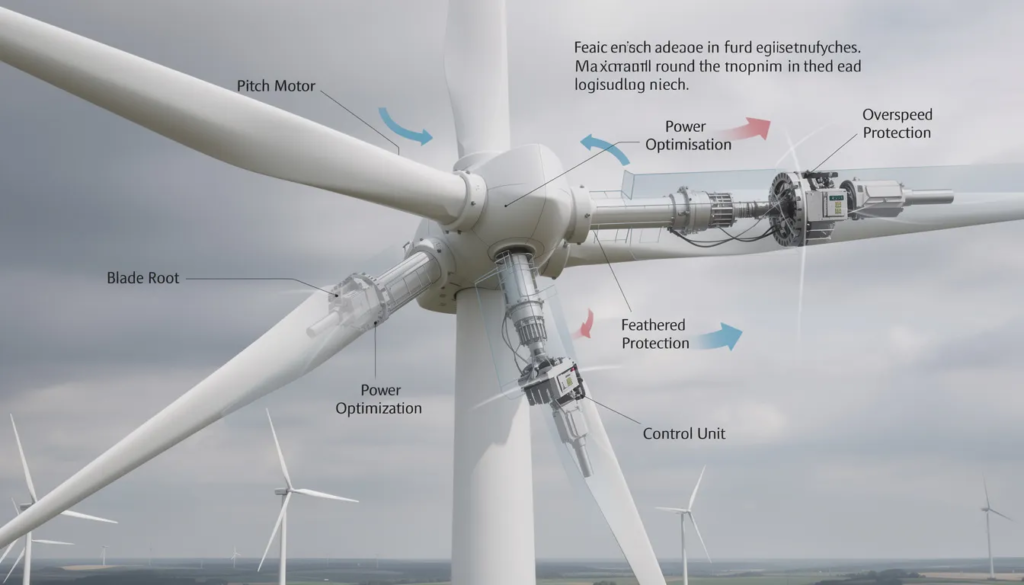

Wind Turbine Components

Wind turbines consist of several key components designed to convert wind power into electrical energy efficiently. The main components include:

- Rotor: Multiple blades attached to a central hub, spinning when wind passes over the blades and creating lift and drag forces.

- Nacelle: A streamlined housing atop the tower that contains the gearbox, generator, and control systems.

- Gearbox: Increases the rotor’s speed to optimize generator performance.

- Control Systems: Includes the yaw system, which continuously adjusts the rotor’s direction to face prevailing winds.

- Tower: Supports the blades and nacelle, elevating the turbine to capture stronger winds.

- Wind Vane and Anemometer: Measure wind direction and speed, providing data for optimal turbine orientation.

By coordinating the blades, rotor, nacelle, gearbox, and control systems, wind turbines maintain stable operation and deliver consistent power to the grid.

Understanding Yaw Systems

The yaw system, which includes the yaw motor, is responsible for rotating the nacelle to face the wind, ensuring the wind turbine rotor is always oriented for maximum energy capture. The yaw drive system includes not only the yaw motor, but also sensors, controllers, drive mechanisms, and brakes.

Yaw systems in wind turbines are responsible for aligning the nacelle and rotor with the wind. Both passive and active yaw systems exist, with active systems being the standard in modern horizontal-axis wind turbines (HAWTs). Vertical-axis wind turbines (VAWTs) typically don’t require yaw systems because their design allows them to face the wind from any direction.

Active yaw systems receive wind direction data from sensors and use control systems to adjust the nacelle’s position. The yaw drive is a key part of this system, powered by motors, gears, and brakes to ensure the nacelle faces the wind for optimal power generation. External components like wind vanes and anemometers provide the necessary data for these adjustments.

Air pressure differences across the blades create lift and drag forces, causing the rotor to spin and generate electricity. The yaw system’s role in maintaining the correct orientation is vital for maximizing energy capture and turbine reliability.

Yaw Motor Selection

A yaw motor is the component responsible for rotating the nacelle to face the wind, working as part of the larger yaw drive system.

Key Selection Criteria

Choosing the right yaw motor is critical for wind turbine performance. Factors such as efficiency, reliability, and weight must be considered. AC motors are common in yaw systems due to their high torque and precise control capabilities. AC-driven electric brakes add safety and reliability.

Leading Manufacturers

Manufacturers like Baolei Electric and Lafert offer yaw motors with high efficiency, some meeting IE5 class standards. Remanufactured yaw motors, such as those from Warfield Electric, come with upgrades like improved brakes and precision-machined bearing surfaces to meet the demanding needs of wind turbines.

Environmental Considerations

Motors must endure harsh environments and provide stable operation. Features like high-quality insulation and protective measures are essential. Advanced control systems also help optimize motor performance and reduce wear over time.

In my experience, selecting a motor with proven durability and good manufacturer support pays off in long-term reliability.

Yaw Drive Systems

Modern Yaw Drive Technologies

Yaw drive systems continue to evolve, focusing on increasing efficiency, reducing wear, and improving overall turbine performance.

Modern yaw drives often use permanent magnet motors paired with inverter controls for precise nacelle positioning. Compared to traditional hydraulic systems, electric or pneumatic brakes simplify the system and reduce environmental risks like hydraulic fluid leaks. Each braking solution involves trade-offs between cost, reliability, and environmental impact.

Example Yaw Motors

For example, the Bonfiglioli 3.5 kW Yaw Motor, designed for Suzlon turbines, features upgraded brakes and precision-machined bearing surfaces. The VEM 3.6 kW Yaw Motor, used in GE turbines, includes high-temperature class H insulation and inverter-duty wiring for durability. The AMP8000 drive system offers efficient operation and maintains safety even during grid fluctuations. Its servo drive design allows decentralized control, saving space inside the nacelle.

Torque and Gearbox Considerations

Electric and hydraulic motors in yaw systems deliver torque through gearboxes to rotate heavy nacelles. Designing these systems to minimize brake wear is essential for reliable, efficient operation. High torque density motors can also reduce nacelle weight, improving overall turbine performance.

Control Technology

Advanced Control Features

Yaw systems rely on advanced control technologies to maximize performance and limit wear. Features like adjustable acceleration and braking help extend component life.

Safety Mechanisms

PC-based control platforms offer flexible, high-performance management of yaw drives. Modular software and dedicated controllers allow customization for different turbine sizes and configurations.

Safety features such as STO/SS1 and TwinSAFE logic ensure secure operation, reducing risk during maintenance or fault conditions.

Customization and Flexibility

Modern control systems are designed for adaptability, allowing wind turbines to be tailored to specific site conditions and operational requirements.

With robust control technology, the yaw system can maintain precise alignment with wind direction, which is essential for optimal energy capture.

Wind Direction Alignment

Precise alignment with wind direction is key to maximizing energy capture. The yaw system uses data from wind vanes and anemometers to adjust the nacelle’s position automatically.

These systems are designed to reduce wear and increase reliability through friction reduction and safety mechanisms. Advanced controls may also incorporate predictive maintenance and real-time monitoring to anticipate issues before they cause downtime.

Maintenance and Repair

Regular maintenance is vital to keep wind turbines running efficiently. Predictive maintenance and real-time monitoring help identify potential problems early, minimizing downtime.

Maintenance teams need proper tools and training to perform repairs efficiently. A strategy focused on condition-based and reliability-centered maintenance can extend turbine life and reduce costs.

I’ve seen this fail when maintenance schedules are neglected, leading to unexpected breakdowns and costly repairs.

System Solutions

Role of the Yaw System

Modern wind turbine systems aim for maximum efficiency and reliability under varying conditions. The yaw system plays a central role by keeping the rotor aligned with the wind.

Engineering Innovations

Robust motors and precision gearboxes enable quick, accurate nacelle adjustments. Innovative materials and engineering reduce wear on key components like gearboxes and bearings, extending turbine lifespan.

Grid Integration

High-performance electrical systems convert mechanical energy into electricity that feeds the grid. Manufacturers like Baolei Electric are also improving how wind power plants integrate with the electrical grid, ensuring stable renewable energy supply to communities.

These comprehensive solutions help optimize turbine output while lowering maintenance expenses and supporting sustainable energy goals.

Benefits of Optimization

Yaw motors are critical in optimizing efficiency in energy production and are designed to enhance the performance and longevity of wind turbines.

The main benefits of optimizing wind turbine performance include:

- Higher efficiency in energy production

- Less wear on mechanical and electrical components

- Lower maintenance costs

- Increased reliability and dependability of turbines

- Improved safety for maintenance personnel

- Greater cost-effectiveness over the turbine’s lifespan

Yaw motors not only improve energy production but also stabilize equipment in other fields, such as camera systems used for filming.

Reducing wear through advanced controls and safety features helps turbines produce more electricity and operate more safely. Predictive maintenance and real-time monitoring are vital tools in this process.

Electrical Energy Output

Electrical output depends on several key factors:

- Wind speed

- Turbine efficiency

- Generator capacity

- Proper installation of yaw systems

- Reliability and integration of modular designs

- Use of electric drives for braking instead of hydraulic systems

- Real-time monitoring and predictive maintenance

Proper installation of yaw systems, especially modular designs that simplify integration without extra external components, improves output by reducing downtime and enhancing reliability.

Using electric drives for braking instead of hydraulic systems further boosts yaw system efficiency and reliability.

Real-time monitoring and predictive maintenance help maintain stable, reliable electricity production.

Conclusion and Future Outlook

Optimizing wind turbine performance remains essential for improving efficiency and reliability. Advanced control systems and safety features are key to these improvements.

The future of wind energy looks promising, with ongoing technological advances and design innovations.

As renewable energy demand grows, wind power will play an increasingly important role. Companies like Baolei Electric will continue to be crucial contributors to this industry.

Further research and development focused on performance, cost reduction, and efficiency improvements will shape the future of wind turbines. Predictive maintenance and real-time monitoring will remain central to these efforts.