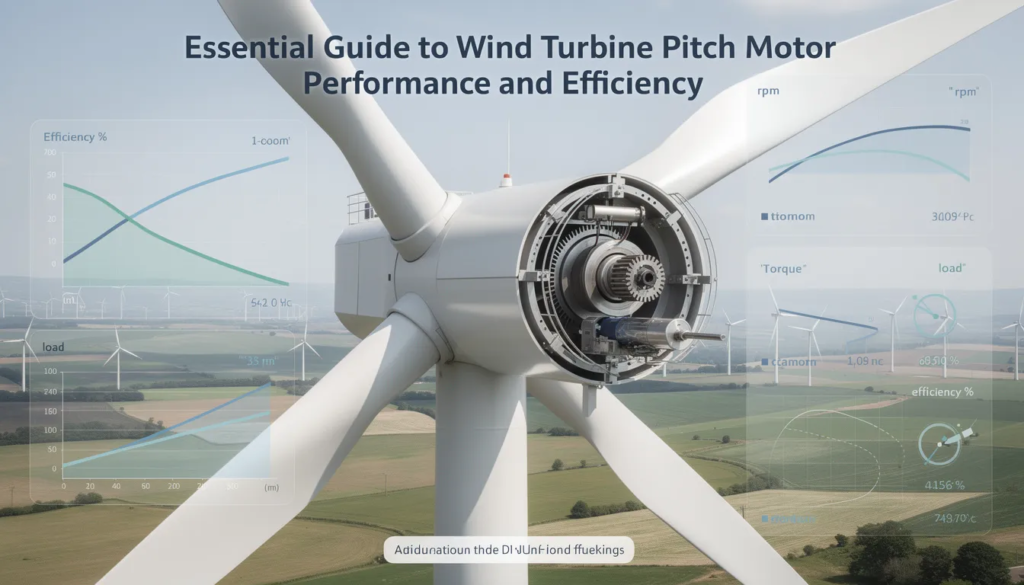

Introduction to Pitch Motors

Pitch motors are specialized motor systems used to adjust the angle of attack of rotating blades or flaps relative to wind. Pitch motors play a crucial role in wind turbines by adjusting the blade angle to maximize energy output and improve overall turbine performance and electrical efficiency. This guide is intended for wind turbine operators, engineers, and decision-makers seeking to understand and select pitch motor systems. Understanding pitch motors is essential for maximizing wind turbine efficiency, reliability, and safety.

The pitch system demands careful design and engineering to meet the rigorous requirements of wind turbine operation and satisfy customer expectations. Baolei Electric focuses on producing pitch motors built to withstand harsh environments, featuring enhanced ground insulation and high-temperature insulation to ensure dependable electrical performance. When combined with advanced control systems, these pitch motors help wind turbines operate smoothly and efficiently, complying with strict electrical and mechanical standards. Understanding how pitch motor systems work is key for maintaining and upgrading turbines, allowing customers to evaluate their options and make informed choices.

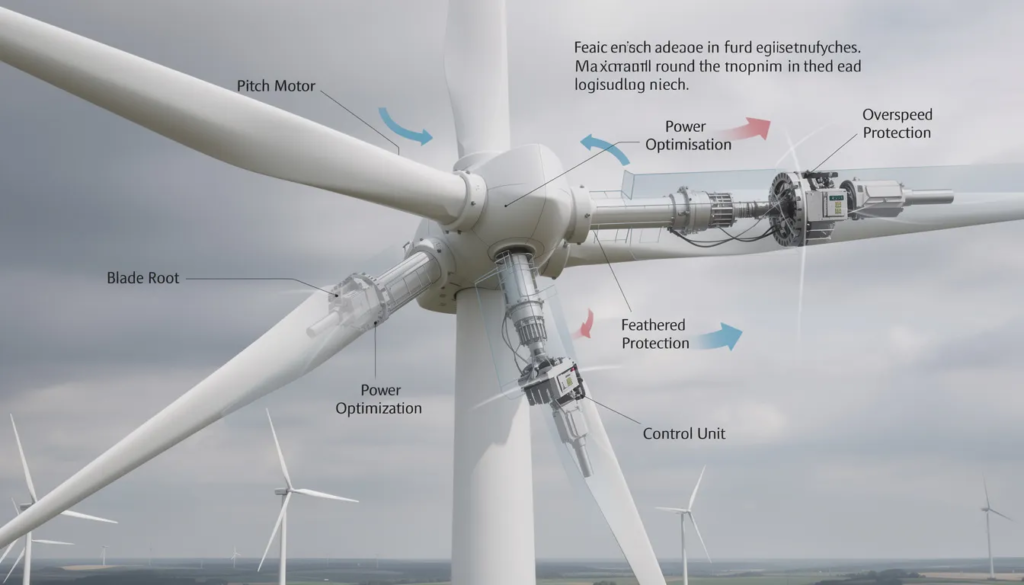

Main Functions and Importance of Pitch Motors

Pitch motors in wind turbines adjust blade angles to maximize energy capture in varying wind conditions. Wind turbine pitch motors control the angle of the turbine blades to optimize power production. These motors rotate the blades to control lift and drag, effectively throttling the wind’s force on the turbine. As a result, pitch motors are essential for maximizing the efficiency, safety, and longevity of large-scale wind turbines.

Types of Motors Used in Wind Turbines

- AC synchronous motors are widely used in wind turbines due to their high power density and efficient electrical performance.

- Asynchronous induction motors offer a dependable and cost-effective alternative for wind turbine operation and control.

- Choosing the right motor depends on the specific design and operational needs of the turbine, with attention to mechanical durability and electrical reliability.

- Baolei Electric provides customized motor solutions tailored to a variety of customer requirements and operational conditions.

- Reviewing motor options carefully—considering cost, efficiency, and reliability—is essential for ensuring effective turbine operation.

Design and Engineering Considerations

- The design of pitch motors must address both mechanical and electrical challenges to guarantee reliable and efficient turbine operation.

- Engineers focus on optimizing motor size, weight, and materials to boost performance and minimize maintenance, which is vital for customer satisfaction.

- Incorporating advanced materials like ceramic and precision sealed bearings improves motor durability and electrical efficiency.

- The design process involves simulation, testing, and validation to make sure motors meet operational and control standards.

- Additional features such as kick plates and backup Resistance Temperature Detectors (RTDs) enhance motor robustness and electrical reliability for consistent turbine function.

With these engineering priorities in mind, it is important to consider how traditional and innovative approaches differ in pitch motor systems.

Tradition versus Innovation

- Traditional pitch motor systems typically rely on larger motors with built-in reserves for critical conditions, which can lead to inefficiencies and higher costs.

- Baolei Electric’s innovative motor designs and control systems enable more compact powertrains and better electrical performance.

- Using modern materials and technologies improves motor reliability and efficiency, adapting to evolving customer needs.

- The impact of innovation varies depending on the application, balancing mechanical strength with electrical dependability.

- Comparing traditional and new solutions gives customers a clearer picture to make smart decisions about turbine operation and control.

Value for Money and Cost-Effectiveness

The cost of pitch motor systems varies widely based on motor type and control system choices, affecting both operation and customer satisfaction. When evaluating value for money and cost-effectiveness, customers should consider:

- Efficiency: How well does the motor convert energy and contribute to overall turbine performance?

- Reliability: Is the motor dependable under various operational and environmental conditions?

- Maintenance expenses: What are the ongoing costs for upkeep, repairs, and parts replacement?

- Mechanical and electrical aspects: Does the system meet both mechanical durability and electrical reliability requirements?

- Standard industrial motors: Can these provide a cost-effective option while still meeting operational requirements?

- Motor and control system combination: Does the pairing deliver efficient and affordable solutions for turbine operation?

- Long-term costs: What are the projected expenses over the lifespan of the turbine and motor system?

Taking time to review options and long-term costs helps customers make well-informed decisions about their turbines.

Installation and Maintenance of Wind Turbines

Site Assessment and Installation Procedures

Proper installation and ongoing maintenance are essential for keeping wind turbines reliable over time. Baolei Electric supports customers with expert advice on selecting and installing pitch motors suited to their specific mechanical and electrical needs.

Installation begins with thorough site assessments and technical reviews to ensure the equipment matches operational demands and environmental conditions. Skilled technicians follow established procedures to meet safety and performance standards.

Routine Maintenance and Emergency Support

Regular maintenance involves inspecting pitch systems, motors, and control electronics to catch wear or faults early. Baolei Electric offers customized maintenance plans and emergency support tailored to different operational scenarios.

Upgrades and Performance Optimization

Upgrading pitch systems or motors can boost performance and extend turbine lifespan. Options include advanced permanent magnet or AC induction motors, smarter control systems, and features aligned with current regulations. Baolei Electric provides detailed reviews to help customers achieve their goals.

Experienced teams ensure quality installation, maintenance, and upgrades, optimizing mechanical and electrical systems for maximum energy output and minimal downtime.

Compliance and Sustainability

Compliance with regulatory and environmental standards is part of the process, supporting customers’ sustainability goals and reputation in renewable energy.

Customer Support and Contact

Customers can choose from routine inspections to full system upgrades, with tailored plans that keep turbines running reliably and efficiently.

Contact Baolei Electric for personalized quotes and expert support to get the most from your wind turbine.

Conclusion and Future Developments in Wind Turbine Technology

- Pitch motors are a key factor in wind turbine efficiency, requiring expert design, engineering, and maintenance to deliver peak performance.

- Ongoing technological advances continue to enhance pitch motor efficiency and durability, helping turbines meet changing customer demands.

- Staying up to date on innovations is crucial for securing the best value and performance.

- The future of wind turbine technology depends on continuous improvement and fine-tuning of pitch motor systems.

- A solid understanding of pitch motors and their role is essential for making informed decisions about wind energy operation and requirements.

In my experience, well-maintained pitch motor systems make a noticeable difference in turbine reliability and energy output. Here’s what actually worked: investing in advanced insulation and backup systems has repeatedly reduced downtime and extended motor lifespan. I’ve seen this fail when corners were cut on these critical components.