Wind power turbine technology has become a cornerstone of renewable energy worldwide, transforming the kinetic energy of wind—which is the movement of air—into usable electrical energy. Air flows, driven by atmospheric conditions, are harnessed by turbines to generate electricity from wind energy. As concerns about climate change and the depletion of fossil fuels grow, wind turbines offer a clean, sustainable alternative to traditional energy sources. Historically, windmills were used for mechanical power and early electricity generation, and modern wind power turbines have evolved from these early designs.

Over the last 20 years, wind power has delivered nearly $330 billion of investment, underscoring its economic and environmental significance. This article explores how a wind power turbine works, its various types, and its role in the modern energy landscape, featuring insights from Retek Industrial.

Understanding How a Wind Power Turbine Works

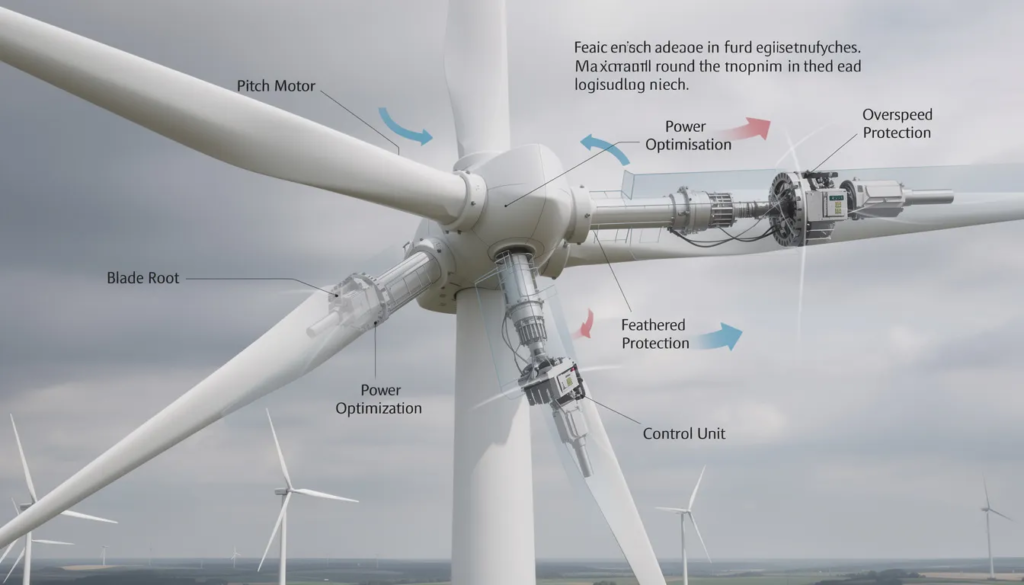

A wind power turbine operates by capturing the wind’s kinetic energy through its rotor blades, which are connected to a main shaft. When wind flows over these blades, it causes them to spin, converting the wind’s kinetic energy into mechanical energy. Wind speed is a key factor in determining how much energy the turbine can capture. This mechanical energy then drives an electric generator, producing electrical energy that can be fed into the power grid. Wind turbines typically produce electricity at a rotation speed of around 1,500–3,000 revolutions per minute, ensuring efficient energy conversion.

The rotor blades, often three in modern wind turbines, are designed to maximize efficiency by harnessing horizontal-axis wind flow. The spinning rotor turns the main shaft, which is connected to the generator. Different types of generators, such as direct-drive and geared generators, are used in wind turbines to convert mechanical energy into electrical energy. In many modern turbines, a direct drive system eliminates the need for a gearbox, improving reliability and reducing maintenance costs.

The aerodynamic force from the rotor blades creates lift and drag, causing the rotor to spin. Wind turbines produce Direct Current (DC) power, which is converted to Alternating Current (AC) electricity by power converters. The electricity generated is then transmitted to the utility grid, where it can be distributed to homes and businesses. The output of a wind power turbine depends on factors such as wind speed and turbine efficiency.

Learn more about the American Wind Energy Association and its role in advancing wind power technology.

Basic Types of Wind Turbines

There are two primary types of wind turbines: horizontal axis wind turbines (HAWTs) and vertical axis wind turbines (VAWTs). The vast majority of wind power plants use horizontal-axis turbines because of their higher efficiency and ability to generate more electricity at varying wind speeds.

The Darrieus vertical axis wind turbine was developed by French inventor Georges Darrieus, whose work provides important historical context for the evolution of VAWTs. Small wind turbines are defined as those smaller than or equal to 100 kilowatts, making them suitable for localized energy needs. The cost to install a small wind turbine can range from $15,000 to $175,000, depending on various factors, such as size, location, and installation complexity. However, residential wind power is not suitable for everyone and is limited by geography and land use. A property must have an average wind speed above 10 or 11 miles per hour to effectively use wind power.

Horizontal Axis Wind Turbines

Horizontal axis wind turbines are the most common type and typically feature three blades mounted on a tower. The design and materials of each blade are crucial for maximizing efficiency and ensuring durability, as blade aerodynamics and structural integrity directly impact energy conversion. These blades rotate around a horizontal axis, aligned with the wind flow to capture the maximum amount of energy. Turbines should be elevated at least 30 feet above nearby trees or buildings to generate adequate energy.

Larger turbines in wind farms can have a rotor diameter spanning several meters. The rotor diameter determines the swept area, which directly affects how much wind energy the turbine can capture. Additionally, rotor diameter influences optimal turbine spacing within a wind farm to maximize efficiency and minimize wake effects. This enables them to produce several megawatts of power. The rotor assembly of a wind turbine includes the blades and hub, which measure about 80 meters in diameter for a typical turbine. The size of wind turbines varies widely, with the largest having electric-generating capacities of about 15,000 kilowatts.

Vertical Axis Wind Turbines

Vertical-axiss turbines, while less common, have blades that rotate around a vertical axis. These turbines can operate in turbulent wind conditions and do not generally require complex yaw mechanisms to face the wind. Vertical-axis turbines, such as the Darrieus turbine, are less common due to their lower efficiency compared to horizontal-axis turbines. Vertical-axis turbines are often used in small wind turbines for residential or urban applications where wind flow is less consistent. Wind turbines can pose a threat to wildlife, particularly birds and bats, but modern technology is mitigating these effects through innovations like radar systems and blade design improvements.

For further technical details, visit the U.S. Energy Information Administration.

Wind Turbine Design

The design of wind turbines is fundamental to maximizing wind energy capture and efficient electricity generation. Modern wind turbines are engineered with precision, featuring a rotor with blades attached to a central hub. As wind flows over the blades, the rotor harnesses the wind’s kinetic energy and transforms it into mechanical energy. This energy is then transferred through a gearbox, which increases the rotational speed before it reaches the generator. The generator is responsible for converting this high-speed mechanical energy into electrical energy that can be supplied to the grid.

Horizontal-axis wind turbines are the most common type used today, thanks to their ability to operate efficiently across a wide range of wind speeds. These turbines are designed to align with the wind, ensuring optimal energy capture. The American Wind Energy Association has established rigorous standards for wind turbine design, ensuring that turbines are not only efficient but also safe and reliable for long-term operation. Every aspect of a wind turbine—from the aerodynamic shape of the blades to the durability of the generator—contributes to its overall efficiency and performance in harnessing wind energy. Horizontal-axis wind turbines are the most common type and have blades similar to airplane propellers.

The Role of Wind Farms and Offshore Wind Turbines

Wind farms, which consist of multiple wind turbines grouped together, are crucial for scaling wind power capacity. These installations are designed to produce electricity at scale for the power grid and can be located on land or offshore. Offshore wind turbines are typically larger and capable of harnessing stronger and more consistent winds found over large bodies of water, leading to higher capacity factors and more electricity generated.

The capacity factor measures the actual energy produced by a wind farm compared to its maximum possible output, and modern wind farms often achieve capacity factors above 40%, demonstrating their effectiveness in generating electricity consistently across varying wind conditions. Wind farms utilize land efficiently, allowing surrounding areas to be used for agriculture or grazing.

Offshore wind farms have become increasingly popular due to their ability to produce significant amounts of renewable energy without occupying valuable land space. A typical offshore wind farm generates enough electricity to power thousands of homes, making a substantial contribution to the grid. They are connected to the electric grid through underwater cables, contributing to the utility grid’s power supply.

Producing Electricity

The process of producing electricity from wind energy is a sophisticated yet elegant sequence of energy conversion. It begins when the rotor blades of wind turbines capture the wind’s kinetic energy, causing the rotor to spin. This mechanical energy is then transmitted to a gearbox, which increases the rotational speed to a level suitable for electricity generation. The high-speed rotation is fed into a generator, where it is converted into electrical energy.

Once generated, this electricity is transmitted from the wind turbine to the power grid. From there, it is distributed to homes, businesses, and industries. Wind farms, which consist of multiple wind turbines working together, can significantly boost wind power capacity and provide a substantial source of renewable energy. Offshore wind turbines, in particular, are capable of producing large amounts of electricity due to the consistently high wind speeds found over open water. As a result, offshore wind farms are playing an increasingly important role in meeting global energy demands and expanding the share of renewable energy in the power grid. However, wind energy is variable and requires backup power sources or energy storage solutions for reliable generation.

Advantages of Modern Wind Turbines

Modern wind turbines are designed for maximum efficiency and cost-effectiveness. Advances in materials and engineering have led to larger rotor diameters and taller towers, allowing turbines to capture wind at higher altitudes where wind speeds are greater. This results in more electricity produced per turbine. Technological advancements have significantly increased the output of modern wind turbines, enabling them to generate more electricity over time and making them more competitive with other energy sources.

Modern wind turbines can generate usable amounts of electricity over 90% of the time, showcasing their reliability and efficiency in energy production. The maximum theoretical power output of a wind turbine is determined by Betz’s law, which states that a turbine can capture a maximum of 59.3% of the kinetic energy of the wind.

The American Wind Energy Association highlights that wind energy is one of the most cost-effective renewable energy sources today. With capacity factors improving due to technological advancements, wind power plants can operate more consistently, providing reliable energy to the grid. While solar power relies on the sun and can be more economical in some regions, wind power can deliver higher output in areas with strong and consistent wind, making it a more effective solution under certain site-specific conditions.

Maintenance and Repair

Regular maintenance and timely repair are essential for ensuring that wind turbines operate efficiently and safely throughout their lifespan. The maintenance process typically involves routine inspections of key components such as blades, the generator, and the gearbox. Technicians check for signs of wear, damage, or fatigue, and perform necessary repairs or replacements to prevent unexpected breakdowns. Noise and visual pollution from wind turbines can lead to community opposition, making it important to address these concerns during planning and maintenance.

Modern wind turbines are designed with reliability in mind, often requiring less frequent maintenance than older models. However, scheduled maintenance remains crucial for optimizing performance and minimizing downtime. The cost of maintaining wind turbines is generally much lower than the expense of replacing major components or entire turbines, making regular upkeep a cost-effective strategy for wind farm operators. By investing in proper maintenance, the wind industry ensures that turbines continue to produce clean, renewable energy efficiently and reliably for years to come. Most turbine materials, like steel and copper, are recyclable, but recycling large composite blades remains challenging.

Wind Power in the Energy Mix

Wind power is a vital component of the world’s renewable energy portfolio, alongside solar and other sources. It offers a clean alternative to fossil fuels, reducing greenhouse gas emissions and dependence on non-renewable resources. Wind power is widely used to produce electricity for homes, businesses, and industries. In regions like Missouri, wind energy has become a significant contributor to the local energy mix, demonstrating the versatility and scalability of wind power. Wind energy helps avoid 351 million metric tons of CO2 emissions annually, equivalent to the emissions of 61 million cars.

Wind turbines do not require water for cooling, conserving water resources compared to thermal power plants, which is another advantage of wind energy. Additionally, wind energy is a major climate change solution and is the cheapest source of new electricity in many parts of the country.

The wind industry continues to grow, driven by the increasing demand for sustainable energy solutions. Wind turbines, from single small wind turbines used in residential settings to large wind farms supplying entire communities, play a pivotal role in meeting global energy needs. Wind energy creates job opportunities in manufacturing, installation, and maintenance, further contributing to economic growth and the transition to renewable energy.

Conclusion: The Future of Wind Power Turbine Technology

Wind power turbines harness the natural energy of the wind to produce clean, renewable electricity. Whether through horizontal-axis wind turbines or vertical-axis turbines, onshore wind farms or offshore wind installations, the technology continues to evolve, becoming more efficient and cost-effective. As the world shifts towards sustainable energy sources, wind power stands out as a reliable and scalable solution for generating electricity, reducing environmental impact, and supporting the transition to a greener future. Wind turbines emit no greenhouse gases and no waste products during operation.