Windmill turbines have become a cornerstone of renewable energy, providing a clean and cost-effective way to generate electricity. Traditionally, windmills were originally used to grind grain and pump water, serving essential roles in agriculture and daily life. According to the U.S. Energy Information Administration, wind energy has a long history of development and use. As concerns over greenhouse gases and climate change grow, wind turbines offer a viable alternative to conventional power plants by converting the wind’s kinetic energy into electrical energy.

Over time, wind turbines have evolved from mechanical uses like grinding grain and pumping water to modern electricity generation for homes and industries. Research is being conducted to improve the design, arrangement, and operation of wind turbines to maximize energy production. The use of advanced materials in turbine blades is being explored to make them lighter, longer, and more durable. Additionally, wind energy research is focused on understanding airflow around wind turbines to improve efficiency and safety.

This article explores how windmill turbines work, their types, and their role in the expanding wind industry, emphasizing both onshore and offshore wind power developments.

How Wind Mill Turbines Work to Generate Power

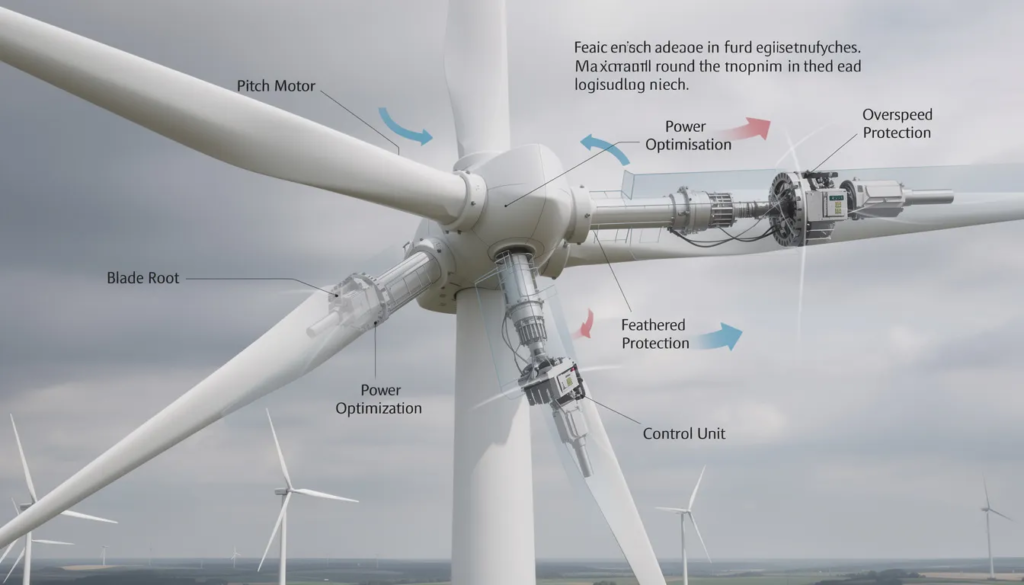

At the heart of wind power generation lies the principle of converting wind’s kinetic energy into electricity. When the wind blows, it moves the wind turbine blades, which are designed like propellers. These rotor blades capture the energy of the wind flow and start to spin. The spinning blades turn a shaft connected to an electrical generator inside the turbine, which creates electricity as the blades spin. The blades’ rotation turns a generator in the nacelle, converting kinetic energy into electrical energy. Inside the generator, magnets rotate within coils of copper wire, producing an electrical current based on electromagnetic induction.

Modern windmill turbines generally have three blades mounted on a tall tower to access higher wind speeds. The height of the tower is crucial because wind speed increases with altitude, allowing turbines to generate more power. The blades of a wind turbine are large, aerodynamically designed structures that capture the wind’s kinetic energy.

The mechanical energy from the rotor blades is transferred through a gearbox or, in some designs, a direct drive system to the generator, which produces electrical energy. A gearbox increases the rotational speed of the blades from around 18-25 revolutions per minute to as much as 1,800 revolutions per minute. This entire system is responsible for generating electricity from wind energy. A single wind turbine can provide enough electricity for a small community or facility.

This electricity is then fed into the power grid through power lines, providing clean energy to local communities and utility grids. The generated electricity’s voltage is increased by a transformer before it is sent through power lines to the electrical grid. Wind turbines produce Direct Current (DC) power, which is converted to Alternating Current (AC) electricity. Wind energy powers homes, businesses, and various devices.

For more detailed technical insights, you can visit the American Wind Energy Association or learn about how wind turbines work from the U.S. Department of Energy.

Types of Wind Mill Turbines: Horizontal and Vertical Axis

There are two primary types of windmill turbines: horizontal-axis turbines and vertical-axis wind turbines. The vast majority of wind turbines in operation today are horizontal-axis turbines, featuring three propeller-like blades. These turbines are highly efficient at capturing wind energy and are commonly used in both small wind turbines and utility-scale turbines. Wind turbines can rotate about either a horizontal or a vertical axis, with horizontal-axis wind turbines (HAWT) being the most common. Savonius wind turbines are drag-type devices that are always self-starting if they have at least three scoops.

Vertical-axis wind turbines, on the other hand, have blades that rotate around a vertical axis. While less common, they offer advantages in specific environments, such as urban areas with turbulent wind flows. Small wind turbines, including single small wind turbines, often utilize vertical axis designs for their simplicity and ability to capture wind from any direction. Vertical-axis wind turbines (VAWT) have the main rotor shaft arranged vertically and do not need to be pointed into the wind to be effective. Darrieus wind turbines, also known as ‘eggbeater’ turbines, are a type of vertical-axis wind turbine that have good efficiency but produce large torque ripple.

Small Wind Turbines: Powering Homes and Businesses

Small wind turbines are transforming the way individuals and small enterprises access renewable energy, offering a practical solution to generate electricity right where it’s needed. Unlike utility-scale turbines found in large wind farms, small wind turbines are designed for localized use, making them ideal for residential properties, farms, and small businesses seeking to provide power independently or supplement their existing energy sources.

These compact turbines typically range from 2 to 10 kilowatts in capacity, making them well-suited for single homes or small commercial operations. By harnessing the wind’s kinetic energy, small wind turbines can significantly reduce electricity bills and reliance on the utility grid, especially in areas with favorable wind conditions. For off-grid locations, small wind turbines can be paired with battery storage to ensure a steady supply of power, even when the wind isn’t blowing.

Installation options are flexible, with both horizontal axis and vertical axis designs available to match different site requirements and wind patterns. Horizontal axis turbines, similar in appearance to their larger counterparts, are popular for their efficiency, while vertical axis models offer advantages in turbulent or variable wind environments. As technology advances and costs decrease, small wind turbines are becoming an increasingly cost-effective way for homeowners and businesses to embrace green energy, reduce their carbon footprint, and contribute to a more sustainable future.

Wind Farms and Offshore Wind Power

Wind farms consist of multiple windmill turbines installed in a specific area to generate large amounts of electricity. These farms can be located onshore or offshore. A wind farm operates as a renewable power plant, generating clean electricity much like a traditional power plant but using wind as its energy source. Offshore wind farms are built in bodies of water, typically on the continental shelf, where wind speeds are higher and more consistent. Offshore wind turbines are generally larger and more powerful than onshore turbines, often several megawatts in capacity. Floating wind turbines are offshore turbines supported by a floating platform, allowing installation in deeper waters.

Wind turbines can be placed on ridges or bluffs to maximize wind access, but this limits the locations where they can be placed. Utility-scale wind turbines typically have capacities ranging from 100 kilowatts up to several megawatts and are mainly utilized to deliver electricity to the power grid.

Managing existing wind turbines is crucial for maximizing efficiency and sustainability. This includes upgrading or repowering existing wind turbines to improve performance, as well as considering the lifecycle of wind farms by decommissioning, reusing, or recycling turbine components. High initial costs are a barrier to the installation of wind turbines, including infrastructure costs. Wind turbine blades represent only a fraction of the overall waste in the US, and 85% of turbine materials are easily reused or recycled.

Offshore wind power has seen rapid growth due to its potential to provide significant amounts of renewable energy. Offshore wind farms connect to the utility grid via underwater transmission lines, supplying electricity to coastal regions. The American Wind Energy Association highlights offshore wind’s capacity to complement solar panels and other renewable sources, contributing to a diversified and resilient energy portfolio.

Economic and Environmental Benefits of Wind Energy

Wind energy is one of the lowest-cost sources of renewable energy, offering economic benefits alongside environmental advantages. It reduces reliance on fossil fuels, thereby decreasing carbon dioxide emissions and other greenhouse gases. Wind turbines emit no greenhouse gases and no waste products during operation. By providing green energy, wind turbines help mitigate climate change and promote sustainable development. Wind energy helps avoid 351 million metric tons of CO2 emissions annually, equivalent to the emissions of 61 million cars.

While some concerns have been raised about the impact of wind turbines on bird populations, studies show that wind energy projects generally have a minimal effect on bird numbers compared to other human-related threats, such as buildings and vehicles. Thousands of birds, including rare species, have been killed by the blades of wind turbines, but the overall impact on bird populations is small. Wind power is far less harmful to wildlife than traditional energy sources it displaces, including birds and their critical habitats.

Wind power capacity continues to expand globally, driven by advancements in turbine technology and increasing demand for clean energy. Modern turbines have higher capacity factors, meaning they produce more electricity relative to their maximum potential, making wind power more cost-effective. Moreover, wind farms create jobs and stimulate local economies, benefiting communities near wind projects. Modern wind farms can generate usable amounts of electricity over 90% of the time. Wind energy has seen a 31% decline in costs over the last decade due to improved technology.

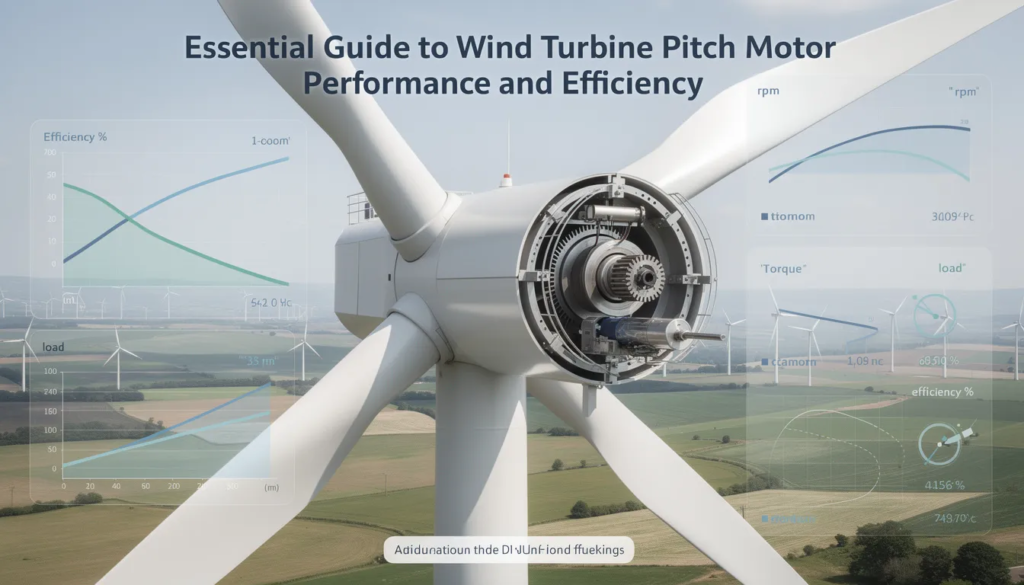

Wind Turbine Maintenance and Efficiency

Ensuring the optimal performance and longevity of wind turbines hinges on regular, proactive maintenance. Routine inspections and servicing are essential for preventing unexpected breakdowns, minimizing downtime, and maximizing the amount of electrical energy generated. The American Wind Energy Association underscores the importance of scheduled maintenance, which includes checking wind turbine blades for wear, inspecting gearboxes and direct drive systems, and maintaining electrical components to keep turbines running smoothly. The nacelle houses crucial power generation components, including the gearbox, generator, and control systems.

Modern wind turbines are engineered with efficiency and reliability in mind. Innovations such as direct drive generators and advanced control systems enable real-time monitoring and adjustment, allowing operators to quickly address any issues and optimize turbine output. Many turbines are now designed for easier access to key components, streamlining maintenance procedures and reducing operational costs.

A key measure of wind turbine efficiency is the capacity factor, which reflects how much energy a turbine actually produces compared to its maximum potential. Thanks to improvements in design, materials, and maintenance practices, modern wind turbines often achieve capacity factors of 45-50% or higher, delivering more energy at a lower cost. Offshore wind turbines, in particular, benefit from stronger and more consistent winds, enabling them to generate more power and achieve even greater efficiency.

As the wind industry continues to innovate, advancements in turbine technology and maintenance strategies are driving down the cost of wind energy and making renewable power more accessible. By prioritizing efficiency and reliability, wind turbines are poised to play an even greater role in meeting global energy needs sustainably.

Integration with the Power Grid and Future Prospects

Integrating wind power into the existing electric grid requires careful management due to the variable nature of wind speeds. Windmill turbines generally require a connection to transmission lines and the utility grid to distribute the electricity they create. Advances in grid technology and energy storage solutions help accommodate the fluctuating output from wind farms. The integration of wind energy into the power grid is being enhanced through sophisticated controls and power electronics. However, wind power’s intermittency means it is not always available, making the energy supply unreliable.

As the wind industry evolves, innovations such as taller towers, improved rotor blades, and direct drive systems enhance the efficiency and reliability of wind turbines. The continued deployment of offshore wind farms and small wind turbines expands access to renewable energy across diverse settings.

Retek Industrial is proud to support the wind energy sector by providing advanced motion control solutions that improve the performance and reliability of windmill turbines.

In conclusion, windmill turbines play a vital role in the transition to renewable energy sources. By harnessing the power of the wind, these turbines provide a clean, sustainable, and increasingly cost-effective way to generate electricity, reduce greenhouse gas emissions, and support economic growth. Wind energy is essential in reducing greenhouse gases, which pose the greatest long-term threat to birds and other wildlife. The future of wind power looks promising, with ongoing technological advancements and expanding wind power capacity worldwide. In 2023, the wind industry invested $10 billion in new projects. Wind energy has delivered nearly $330 billion of investment in the last 20 years.